Countercurrent Leaching of Oil from Meal

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

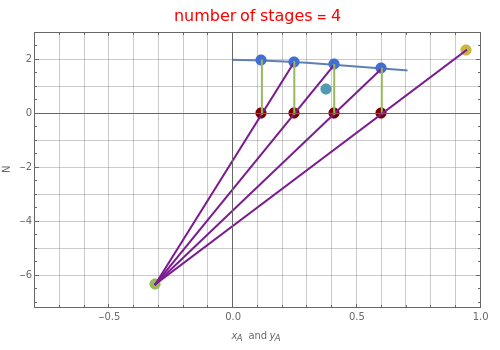

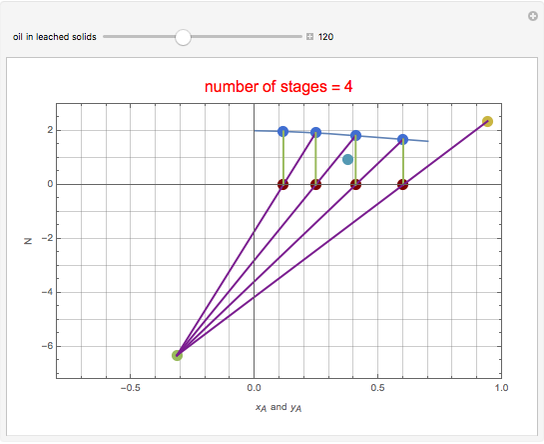

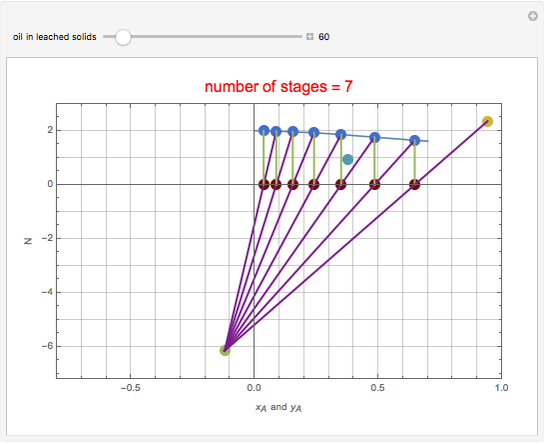

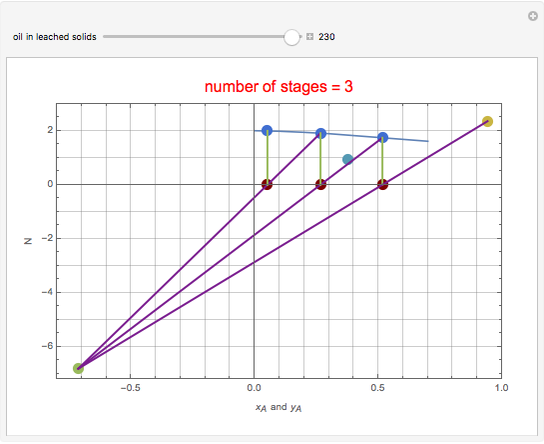

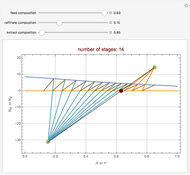

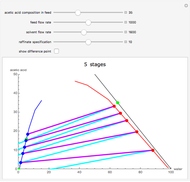

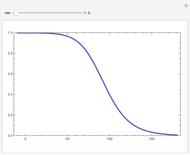

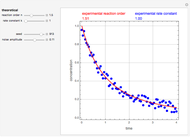

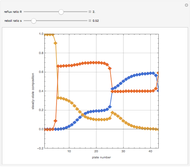

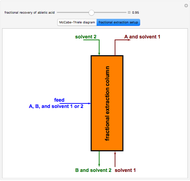

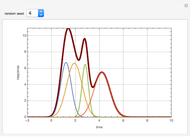

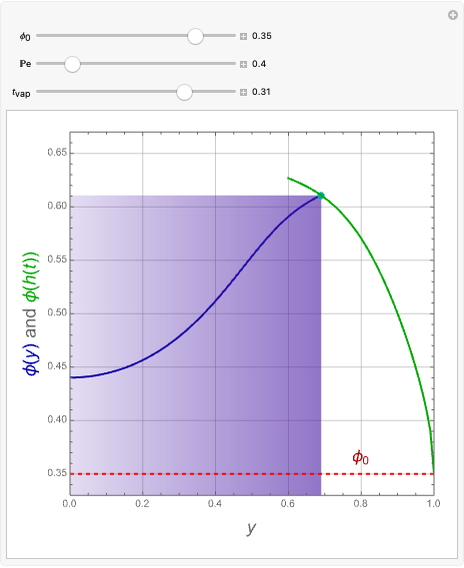

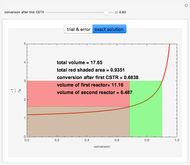

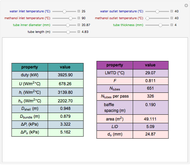

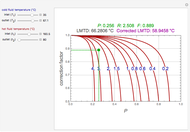

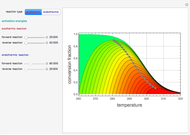

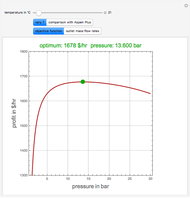

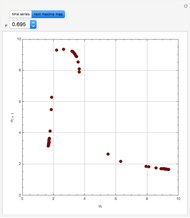

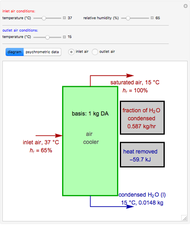

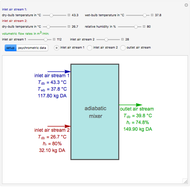

In order to remove a desired solute constituent from a solid phase, leaching with a liquid solvent is used. A device is used to bring the solvent into contact with the solid. Thus, the solute is dissolved in the solvent and separated from the solid. When the solvent is water and the solute is an undesirable component to be removed from the solid, the operation is called washing.

[more]

Contributed by: Housam Binous (March 2011)

Open content licensed under CC BY-NC-SA

Snapshots

Details

C. J. Geankoplis, Transport Processes and Unit Operations, 3rd ed., Englewood Cliffs, NJ: Prentice Hall, 1993.

W. L. Badger and W. L. McCabe, Elements of Chemical Engineering, New York: McGraw-Hill, 1936.

Permanent Citation