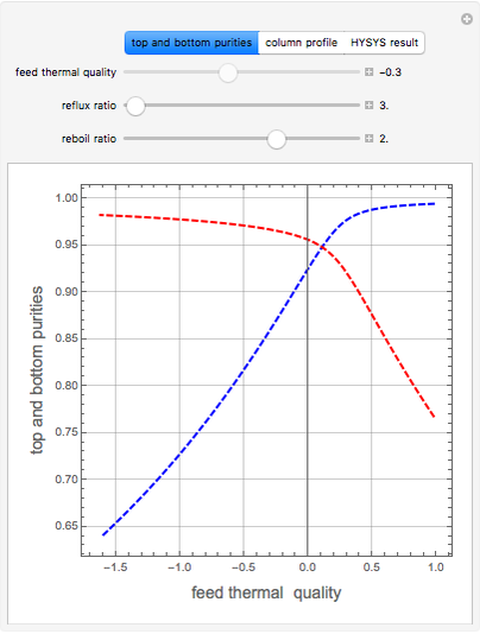

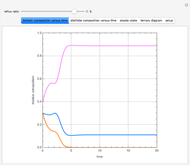

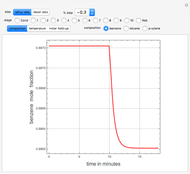

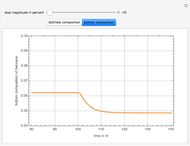

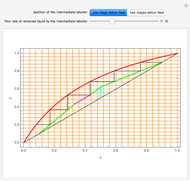

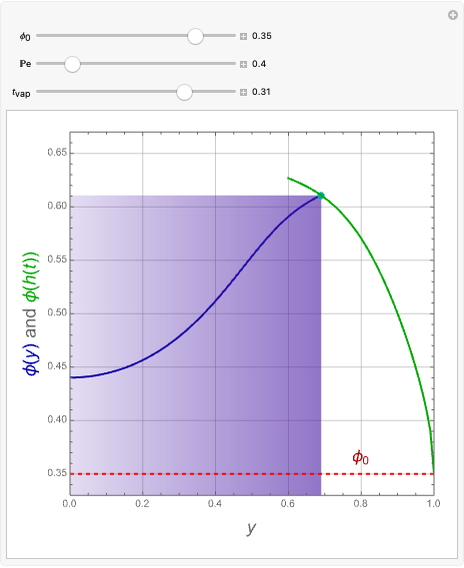

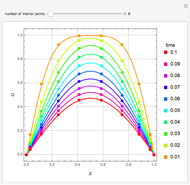

Distillation-Column Product Purity as Function of Feed Thermal Quality

Initializing live version

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

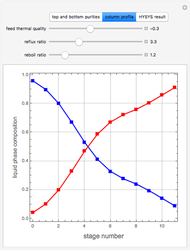

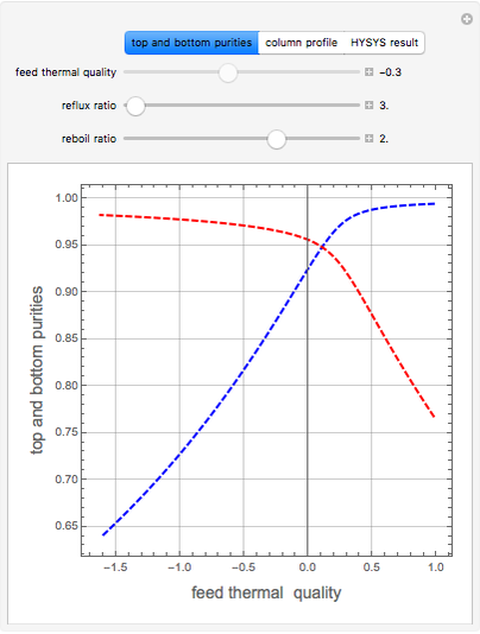

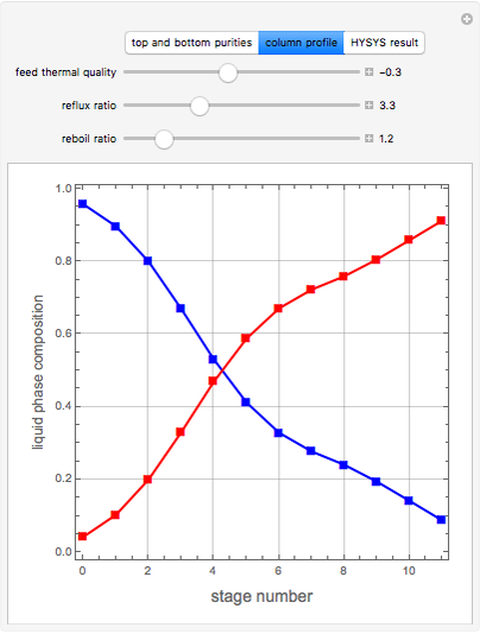

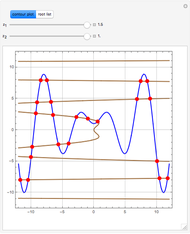

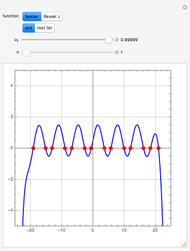

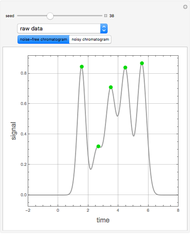

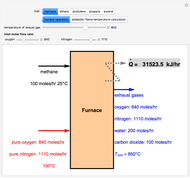

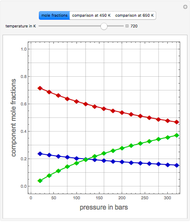

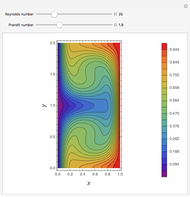

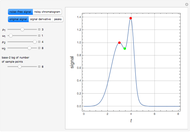

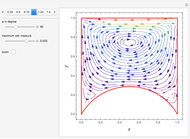

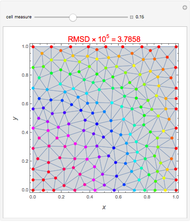

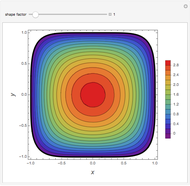

Consider an ideal equimolar binary mixture of benzene and toluene at  . This mixture is fed to a 10-stage column with a total condenser and partial reboiler. The feed stage is stage 7. Column stages are counted from the top. The feed flow rate is taken equal to

. This mixture is fed to a 10-stage column with a total condenser and partial reboiler. The feed stage is stage 7. Column stages are counted from the top. The feed flow rate is taken equal to  . You can set the values of the feed's thermal quality

. You can set the values of the feed's thermal quality  , the reflux ratio

, the reflux ratio  , and the reboil ratio

, and the reboil ratio  .

.

Contributed by: Housam Binous, Ahmed Bellagi, and Brian G. Higgins (January 2014)

Open content licensed under CC BY-NC-SA

Snapshots

Details

Permanent Citation