Operation of an Ideal Belt Conveyor

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

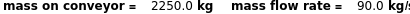

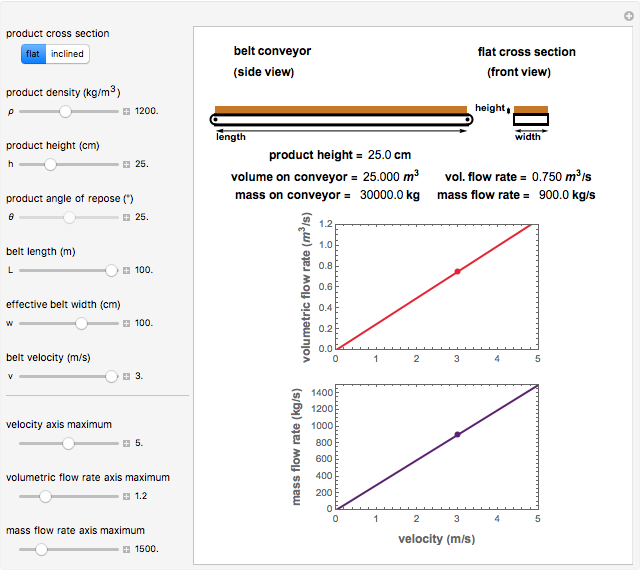

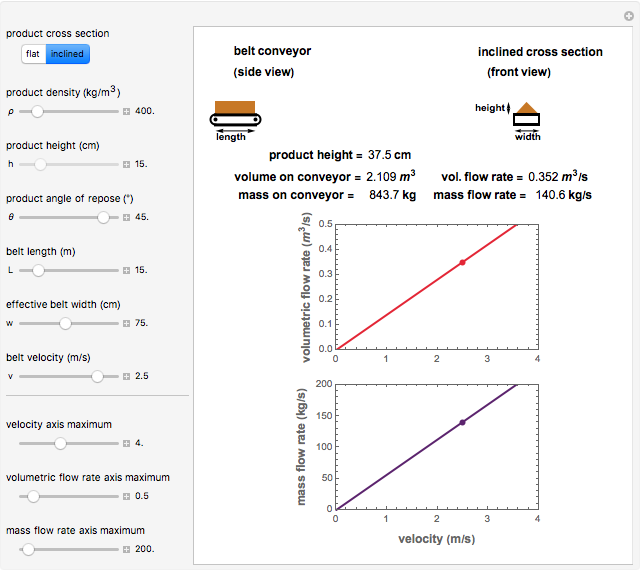

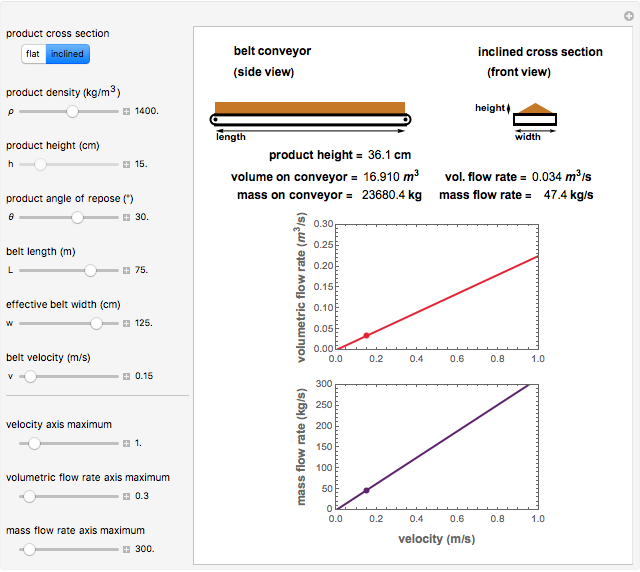

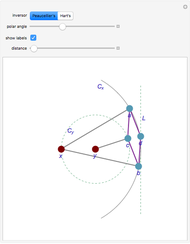

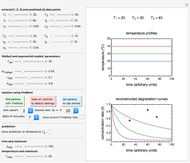

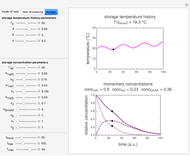

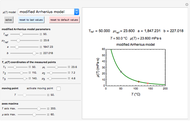

This Demonstration depicts the mass and volumetric flow rates of bulk solids transported on an ideal belt conveyor. It also calculates the volume and mass of the material on the conveyor when it is fully loaded. You can choose between a flat product profile and one that is inclined, in which case the angle of repose is specified rather than the height of the product on the belt.

Contributed by: Mark D. Normand and Micha Peleg (April 2011)

Open content licensed under CC BY-NC-SA

Snapshots

Details

Snapshot 1: long fast conveyor loaded with heavy granular material having a flat cross section

Snapshot 2: short fast conveyor loaded with light granular material having an inclined cross section (45° angle of repose)

Snapshot 3: long slow conveyor loaded with heavy granular material having an inclined cross section (30° angle of repose)

This Demonstration calculates the capacity of an ideal belt conveyor for bulk solids and the mass of material on the belt when it is fully loaded. You can select the cross-sectional profile of the material as either flat or inclined. The adjustable parameters, all entered with sliders, are: the product's bulk density,  (in kg/m

(in kg/m ), its height,

), its height,  (in cm) when the profile is flat or its angle of repose,

(in cm) when the profile is flat or its angle of repose,  (in degrees), when it is inclined, the conveyor's length,

(in degrees), when it is inclined, the conveyor's length,  (in m) and its effective width,

(in m) and its effective width,  (in cm), the belt's velocity,

(in cm), the belt's velocity,  (in m/s), and the maxima of the plots' axes.

(in m/s), and the maxima of the plots' axes.

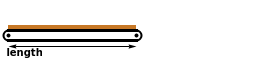

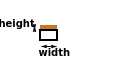

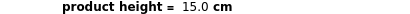

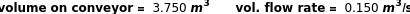

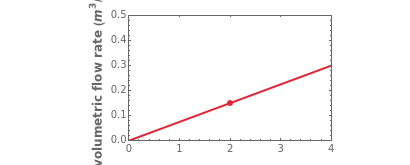

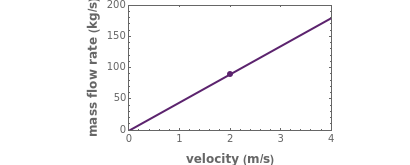

The output displays a schematic view of the belt conveyor from the side and front (not to scale) and the values of the product's height (in cm), the material's volume (in m ) and mass (in kg) on the conveyor, and the volumetric and mass flow rates (in m

) and mass (in kg) on the conveyor, and the volumetric and mass flow rates (in m /s and kg/s, respectively). It also shows plots of the volumetric and mass flow rates versus belt velocity. The dot on the plotted lines responds to the current belt velocity and the other selected parameters.

/s and kg/s, respectively). It also shows plots of the volumetric and mass flow rates versus belt velocity. The dot on the plotted lines responds to the current belt velocity and the other selected parameters.

Not all possible slider-entered values will necessarily correspond to realistic industrial conveyor systems. Note also that in a real, rather than an ideal, conveyor, width is larger than that of the product to avoid spillage and the product's height or angle of repose need not be uniform along the conveyor length.

Permanent Citation