Process-Based Cost Model for Sand-Casting Bronze Bells

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

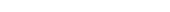

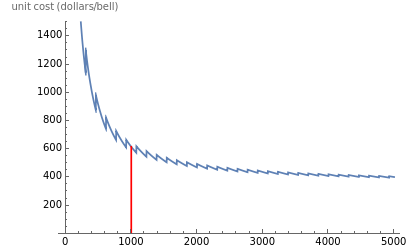

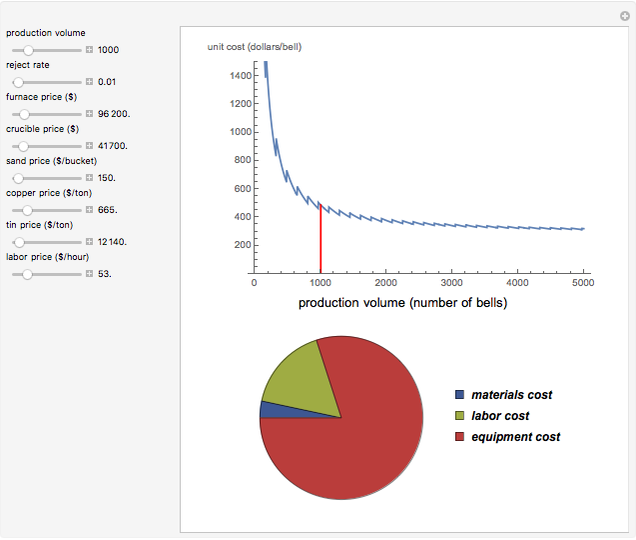

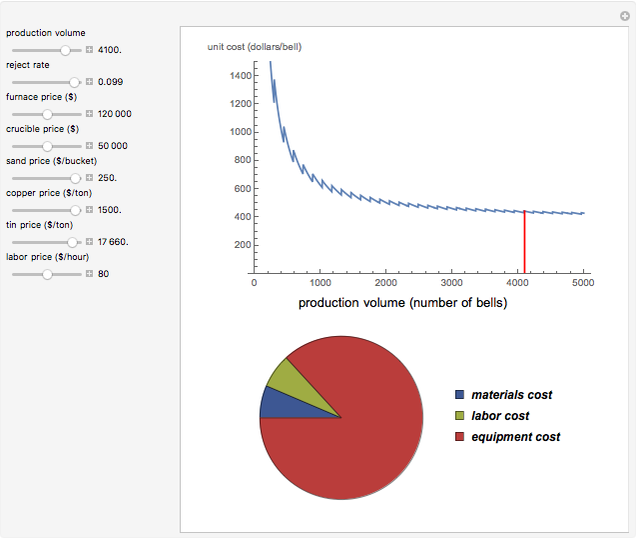

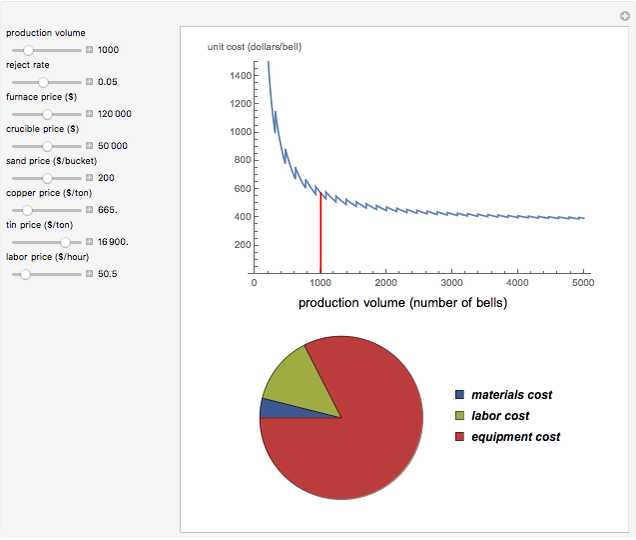

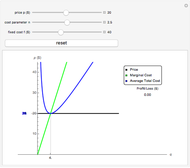

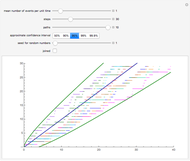

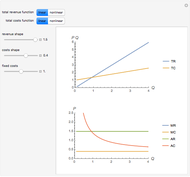

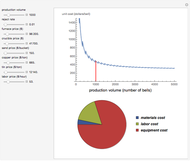

A process-based cost model is used to inform technical decisions. This cost model for sand-casting bronze bells shows how the unit cost and cost distribution vary as a function of materials, labor, and equipment cost, as well as reject rate and production volume. A cost model can be used to identify cost drivers and to address the implications of change in a process or product. Varying the different inputs shows the different relevant costs and their effect on unit cost. The spikes in the cost model represent production volumes which, if exceeded, require purchasing another crucible.

Contributed by: Sam Shames (April 2013)

With additional assistance by: Max Powers, Thomas Villalon, Hanna Vincent, and Stephanie Schafer

Open content licensed under CC BY-NC-SA

Snapshots

Details

This cost model is based on the production of 80/20 copper-tin bells. Assume that melting the metal is never the rate-limiting step, so only one furnace is required. The initial prices for the equipment and materials are based on speaking to industry insiders and online research.

Permanent Citation

"Process-Based Cost Model for Sand-Casting Bronze Bells"

http://demonstrations.wolfram.com/ProcessBasedCostModelForSandCastingBronzeBells/

Wolfram Demonstrations Project

Published: April 26 2013