Safe Operation of a Semibatch Reactor

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

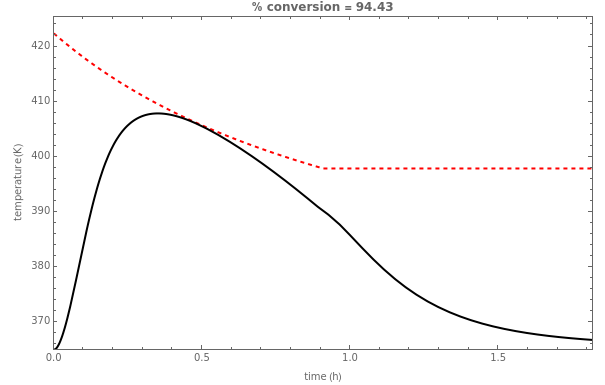

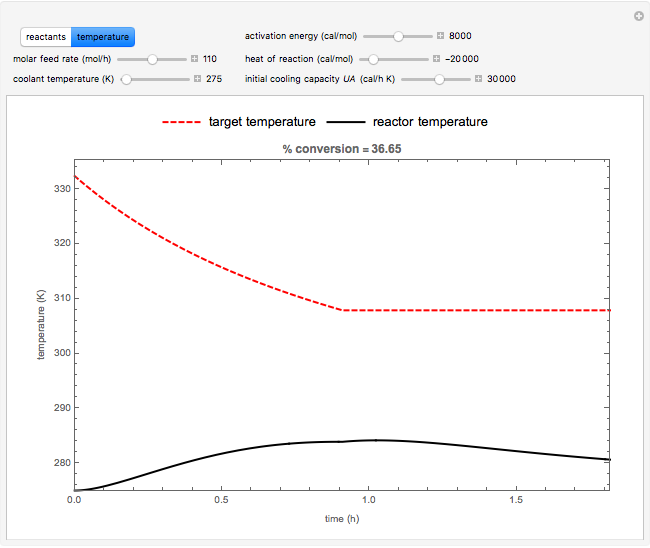

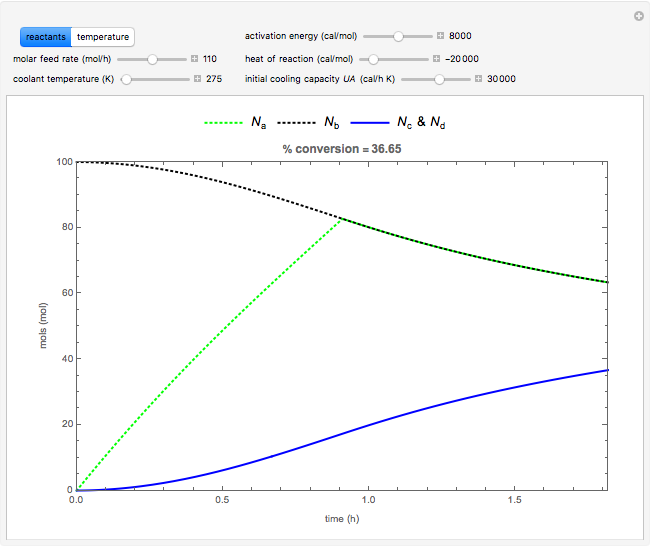

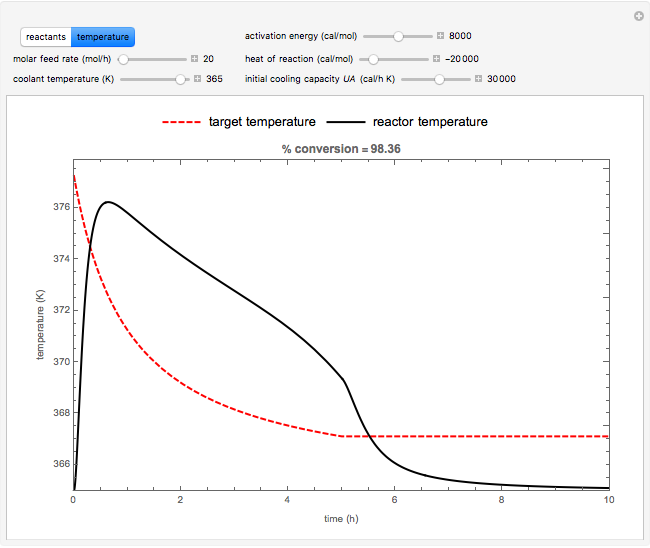

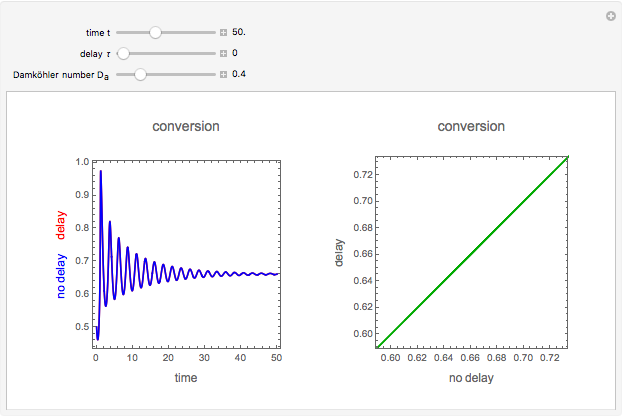

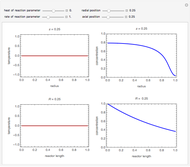

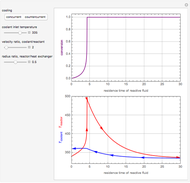

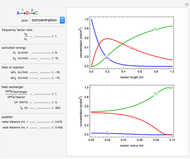

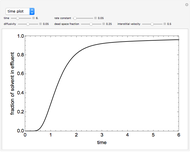

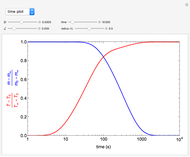

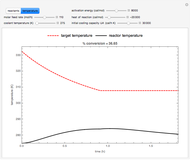

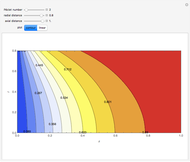

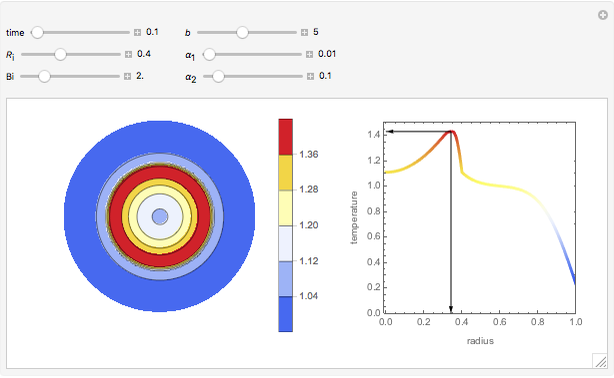

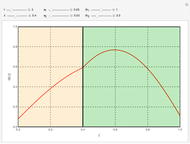

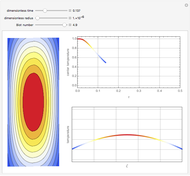

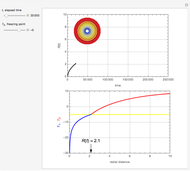

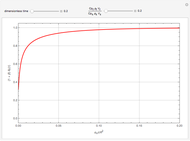

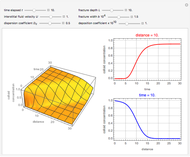

This Demonstration illustrates a method to operate a semibatch reactor to avoid thermal runaways.

[more]

Contributed by: Clay Gruesbeck (December 2017)

Open content licensed under CC BY-NC-SA

Snapshots

Details

The rate law for the reaction is:

The reactant and product concentrations are:

These are the material balances:

The energy balance is:

Initial conditions for these differential equations are:

Reference

[1] K. R. Westerterp, M. Lewak, and E. J. Molga, "Boundary Diagrams Safety Criterion for Liquid Phase Homogeneous Semibatch Reactors," Industrial and Engineering Chemistry Research, 53(14), 2014 pp 5778–5791. doi:10.1021/ie500028u.

Permanent Citation

"Safe Operation of a Semibatch Reactor"

http://demonstrations.wolfram.com/SafeOperationOfASemibatchReactor/

Wolfram Demonstrations Project

Published: December 14 2017