Startup and Steady State in a Chemostat

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

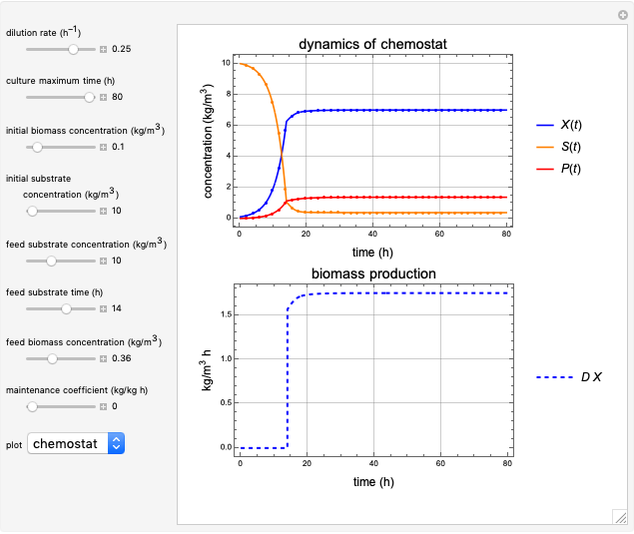

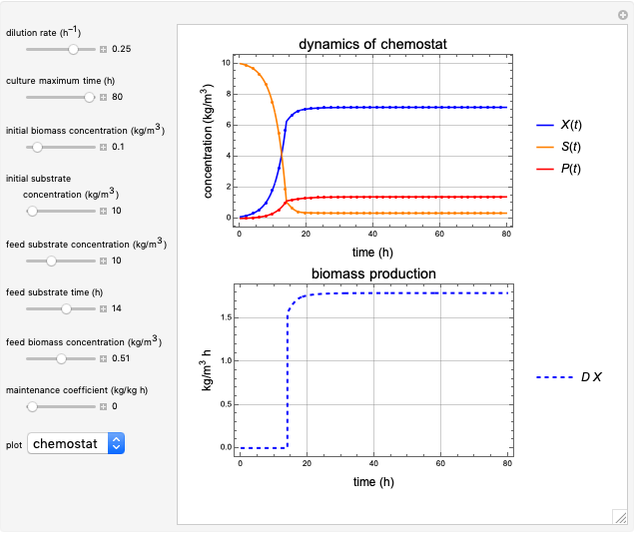

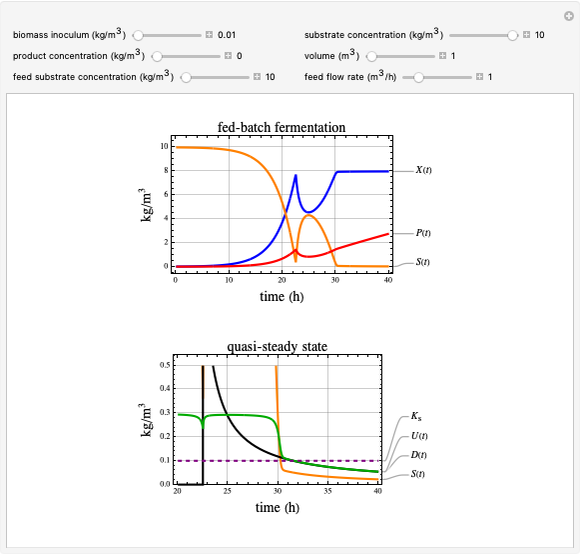

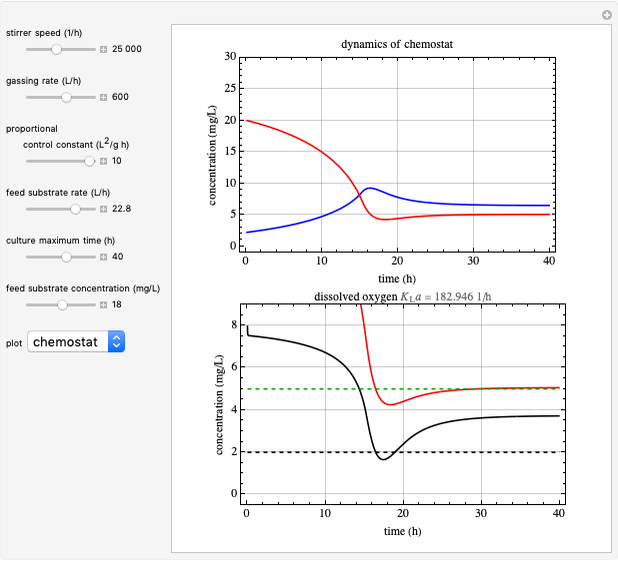

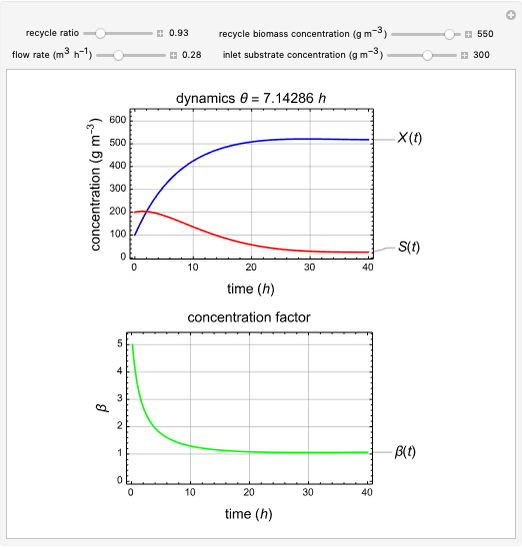

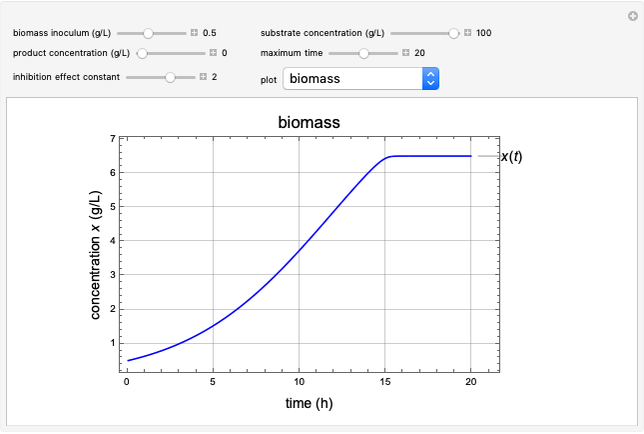

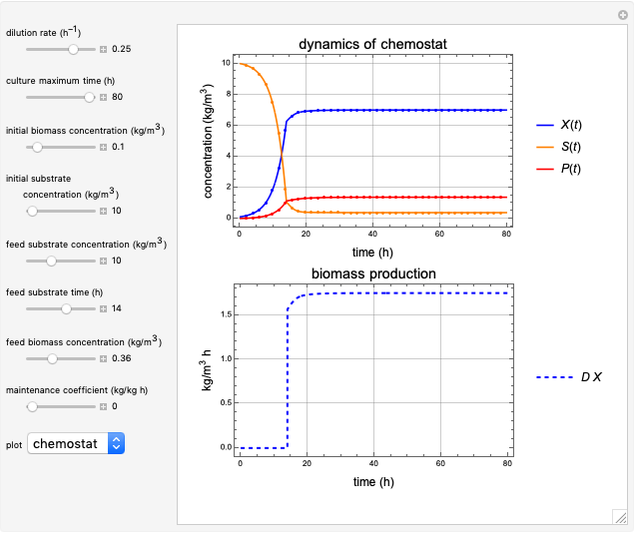

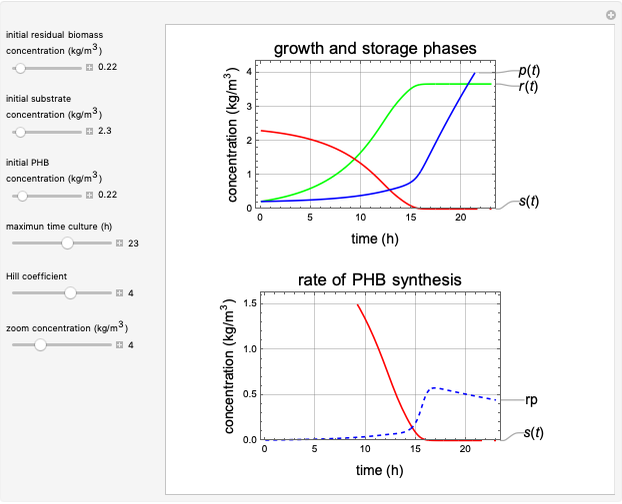

This Demonstration shows the operation of a chemostat. Starting up as a batch reactor, the concentrations change with time. After this short transient period, the bioreactor settles into a steady state.

[more]

Contributed by: R. Ricardo Sánchez (August 2022)

Open content licensed under CC BY-NC-SA

Snapshots

Details

The characteristics of continuous operation are as follows:

Snapshot 1: steady state; after an initial startup period, there is no variation of concentrations with time

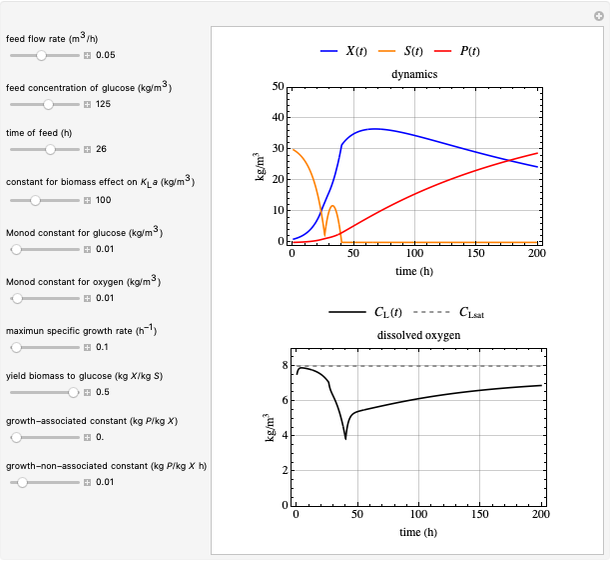

Snapshot 2: constant reaction rates, where  is the biomass reaction rate,

is the biomass reaction rate,  is the reaction rate of the consumed reactant and

is the reaction rate of the consumed reactant and  is the product reaction rate

is the product reaction rate

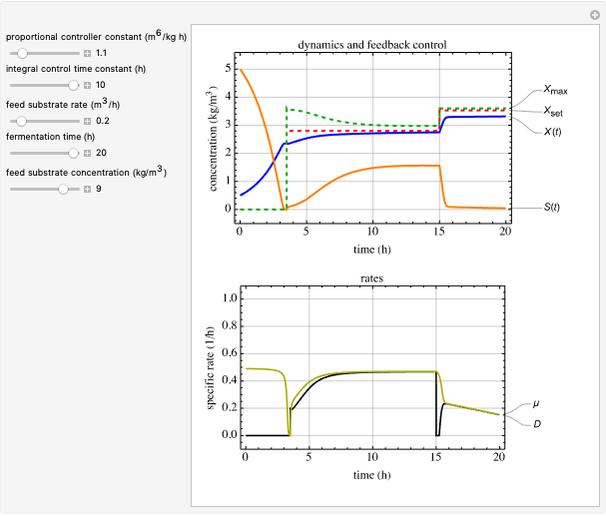

Snapshot 3: Washout of the organisms (cells) will occur when the dilution rate  is greater than the specific growth rate

is greater than the specific growth rate  . This corresponds to the complete removal of cells by flow out of the tank. In many references, including [1], the variables

. This corresponds to the complete removal of cells by flow out of the tank. In many references, including [1], the variables  ,

,  ,

,  and productivity

and productivity  are plotted versus the dilution rate

are plotted versus the dilution rate  , which characterizes the steady state in a chemostat. See Related Links.

, which characterizes the steady state in a chemostat. See Related Links.

Some suggestions for the user:

Increase  interactively to note effect on washout.

interactively to note effect on washout.

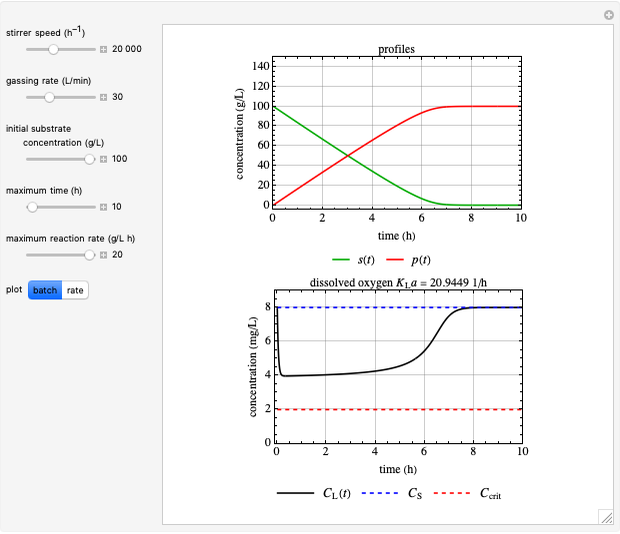

Change the feed substrate concentration  to alter the steady state.

to alter the steady state.

Investigate the influence of maintenance requirements on the steady-state biomass concentration.

Operate initially as a batch reactor with  , and switch to chemostat operation with

, and switch to chemostat operation with  .

.  is the maximum specific growth rate, and in this case was set up to

is the maximum specific growth rate, and in this case was set up to  .

.

Calculate  , the biomass-substrate yield, making use of the yield graph.

, the biomass-substrate yield, making use of the yield graph.

Reference

[1] I. J. Dunn, E. Heinzle, J. Ingham and J. E. Prvenosil, Biological Reaction Engineering: Dynamic Modelling Fundamentals with Simulation Examples, Second Edition, Weinheim, Germany: Wiley-VCH, 2003.

Permanent Citation