Volatility Inversion in Extractive Distillation

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

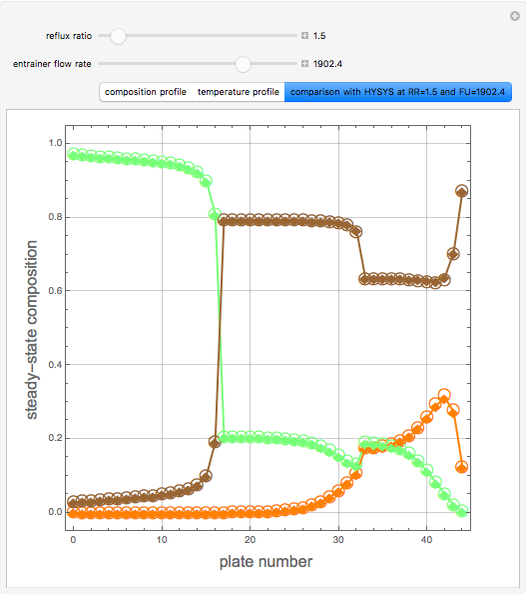

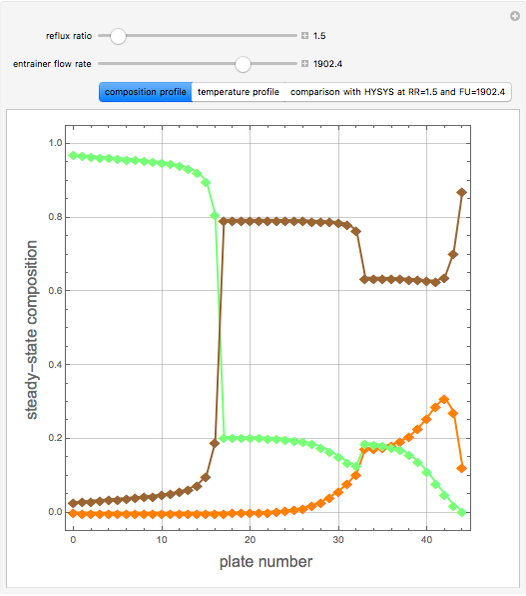

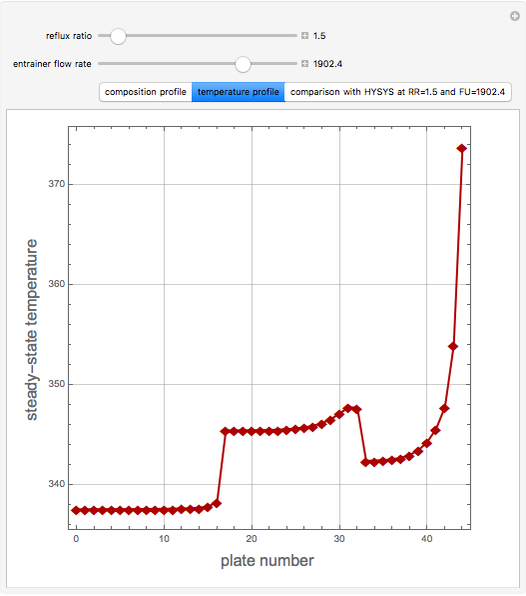

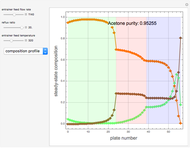

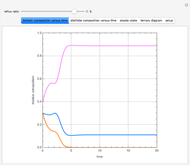

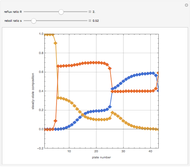

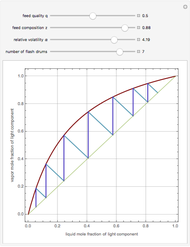

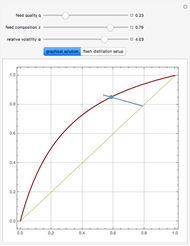

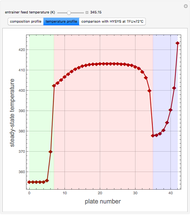

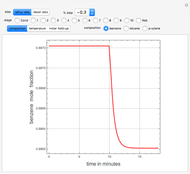

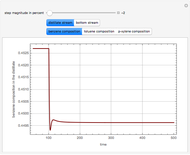

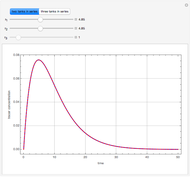

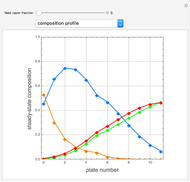

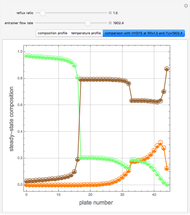

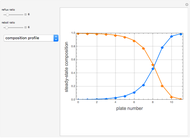

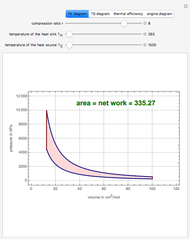

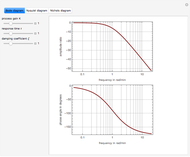

Consider an extractive distillation column operating at atmospheric pressure with 43 stages, a partial reboiler, and a total condenser. It is used to separate acetone and methanol using chlorobenzene as an entrainer.

[more]

Contributed by: Housam Binous and Naim Faqir (July 2012)

Open content licensed under CC BY-NC-SA

Snapshots

Details

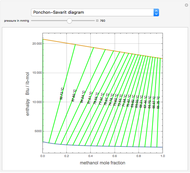

The expressions for pure component vapor and liquid enthalpies were adapted from Aspen HYSYS.

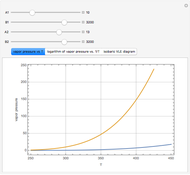

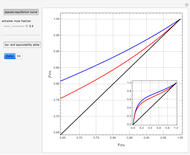

The mixture is assumed to obey modified Raoult's law, and activity coefficients are predicted using the Wilson model.

References

[1] M. F. Doherty and M. F. Malone, Conceptual Design of Distillation Systems, Boston: McGraw-Hill, 2001.

[2] E. J. Henley and J. D. Seader, Equilibrium-Stage Separation Operations in Chemical Engineering, New York: Wiley, 1981.

[3] W. L. Luyben and I.-L. Chien, Design and Control of Distillation Systems for Separating Azeotropes, Hoboken, NJ: Wiley, 2010.

Permanent Citation