Dynamics of an Enzymatic Aerated Reactor

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

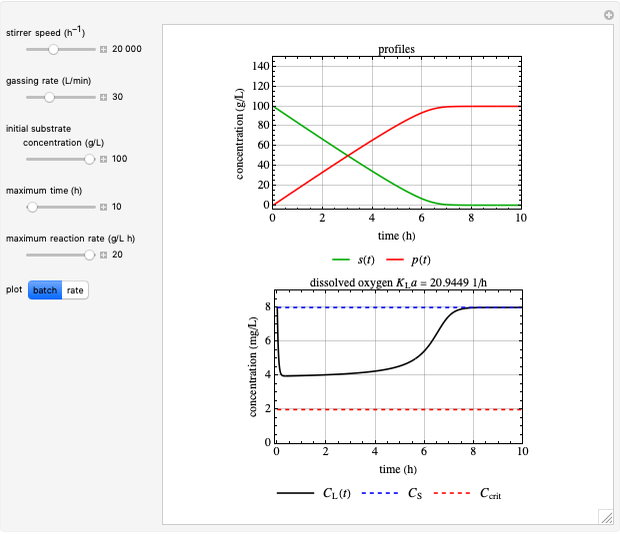

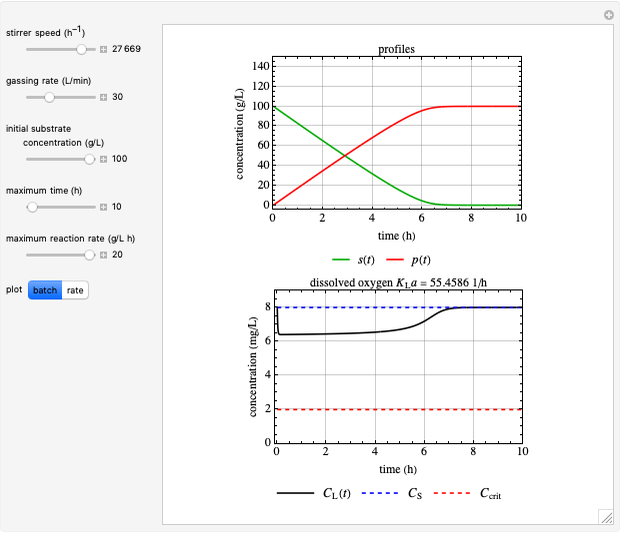

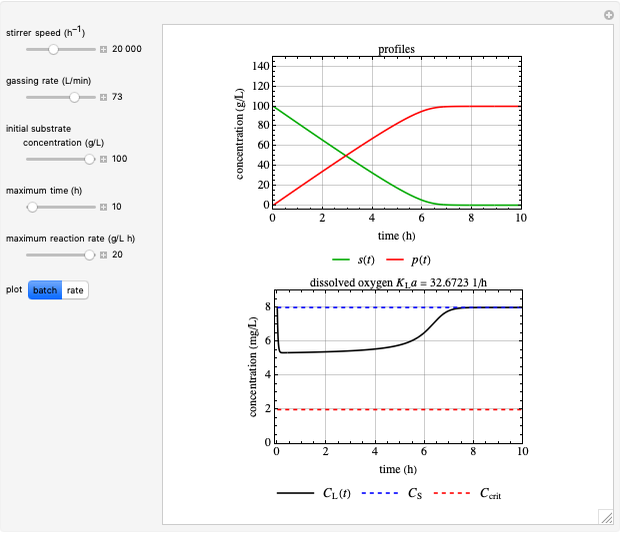

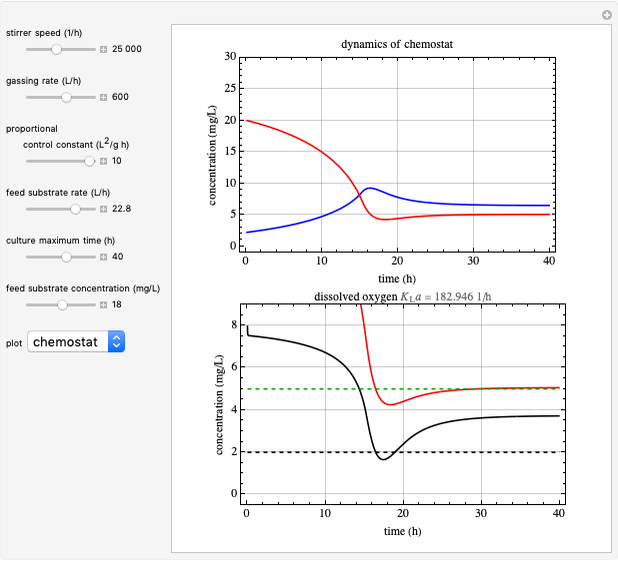

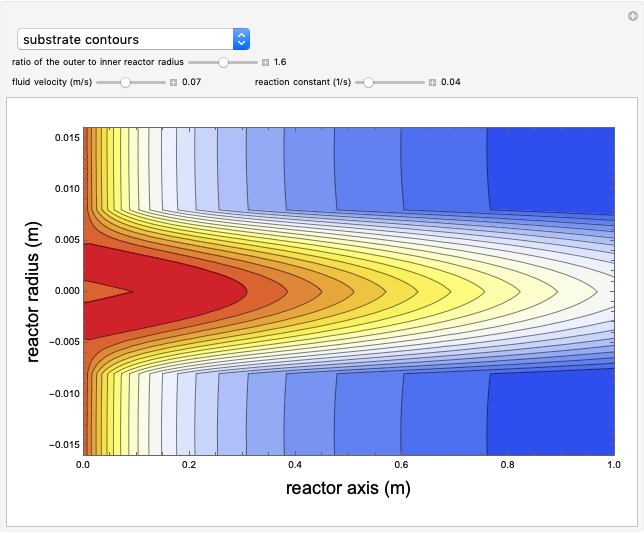

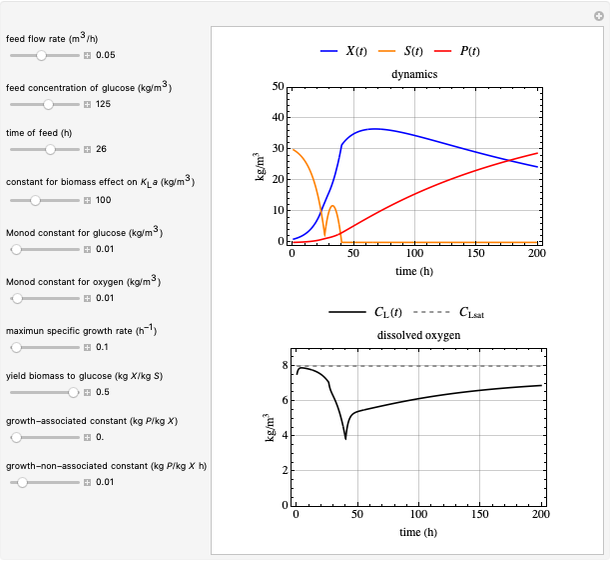

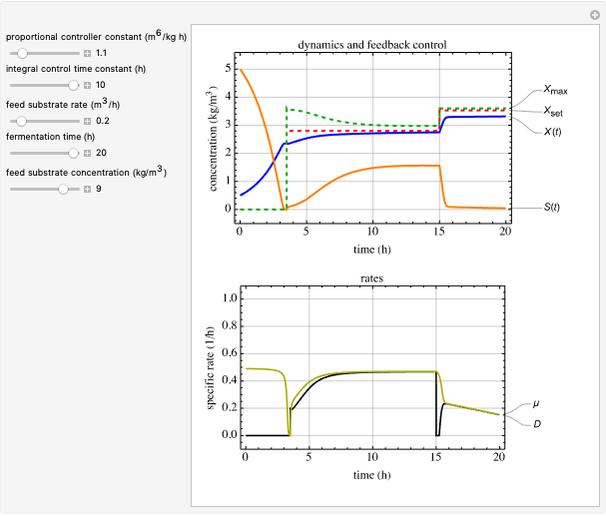

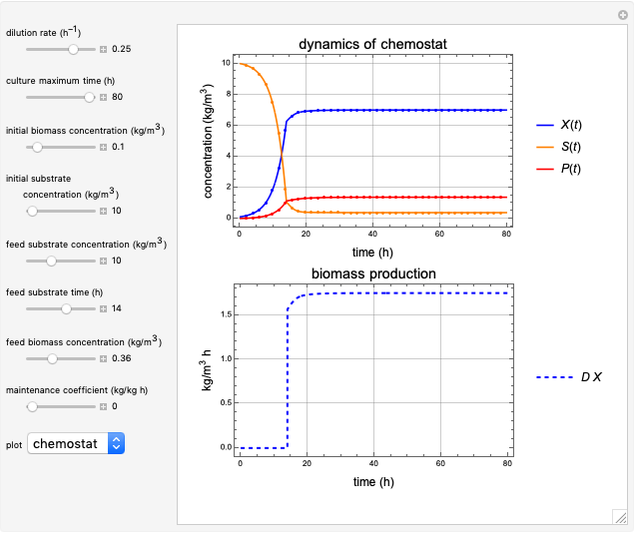

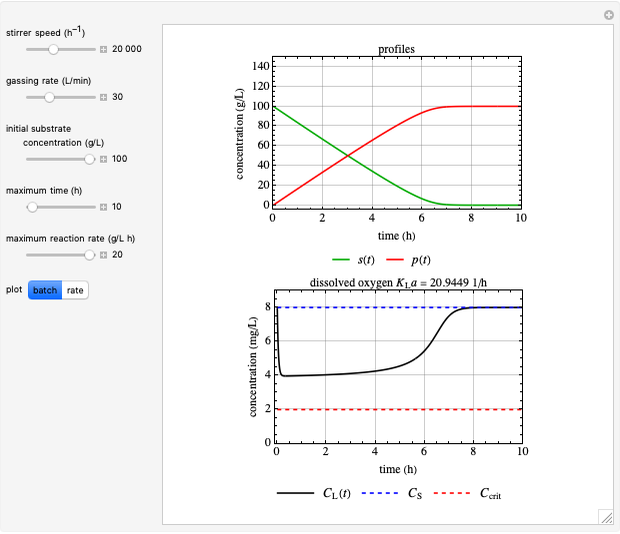

This Demonstration shows the influence of gassing rate  and stirrer speed

and stirrer speed  on an enzymatic aerated reactor. The transfer coefficient

on an enzymatic aerated reactor. The transfer coefficient  is a function of

is a function of  and

and  .

.

Contributed by: R. Ricardo Sánchez (August 2022)

Open content licensed under CC BY-NC-SA

Snapshots

Details

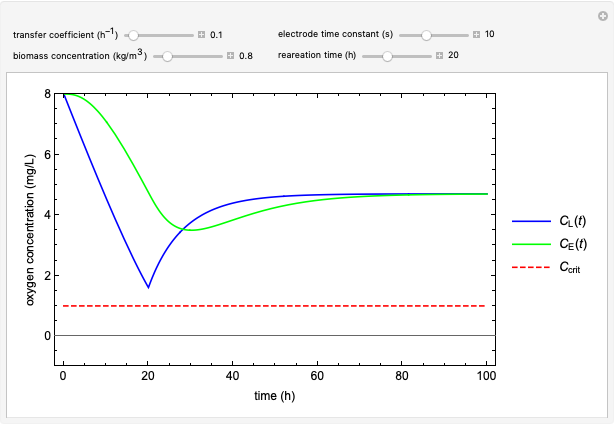

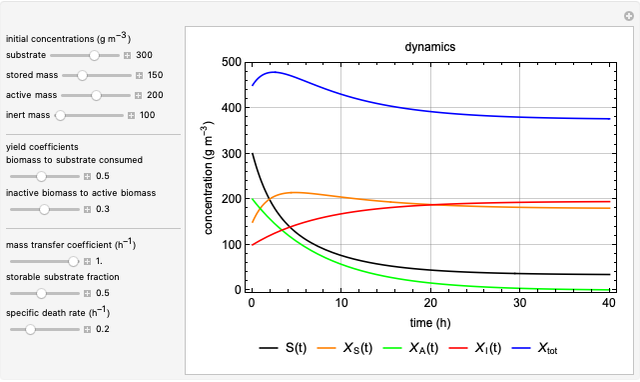

The solubility of oxygen in aqueous solutions at ambient temperature and pressure is only between 8 and 10 ppm. This amount of oxygen is quickly consumed in aerobic cultures and must be constantly replaced by sparging (bubbling air through the liquid) [1].

Notation:

: substrate concentration (g/L)

: substrate concentration (g/L)

: product concentration (g/L)

: product concentration (g/L)

: dissolved oxygen concentration (mg/L)

: dissolved oxygen concentration (mg/L)

: saturation dissolved oxygen concentration (mg/L)

: saturation dissolved oxygen concentration (mg/L)

: critical dissolved oxygen concentration (mg/L)

: critical dissolved oxygen concentration (mg/L)

: substrate uptake rate (g/L h)

: substrate uptake rate (g/L h)

The transfer coefficient  varies with

varies with  and

and  according to:

according to:

with

with  .

.

The model that includes reaction kinetics and mass balances is described in [2].

References

[1] P. M. Doran, Bioprocess Engineering Principles, Boston: Elsevier, 1995.

[2] I. J. Dunn, E. Heinzle, J. Ingham and J. E. Prvenosil, Biological Reaction Engineering, 2nd ed., Weinheim, Germany: VCH Verlagsgesellschaft mbH, 2003.

Permanent Citation