Parallel Plate Heat Exchanger

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

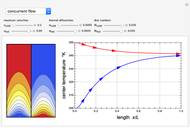

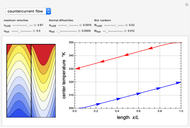

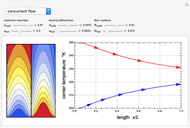

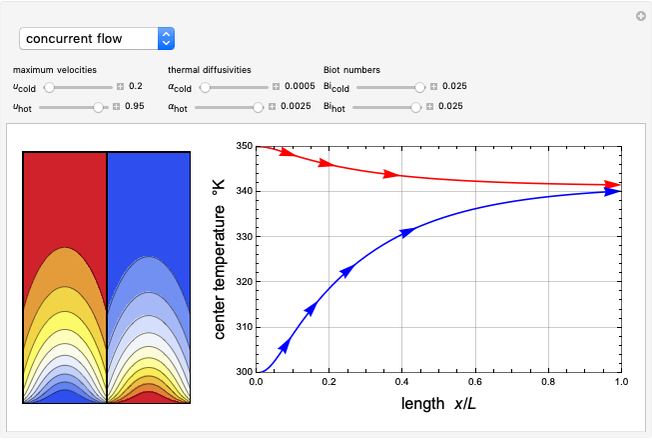

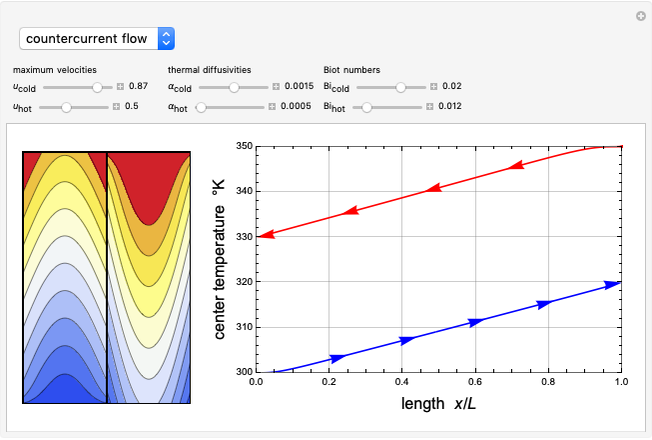

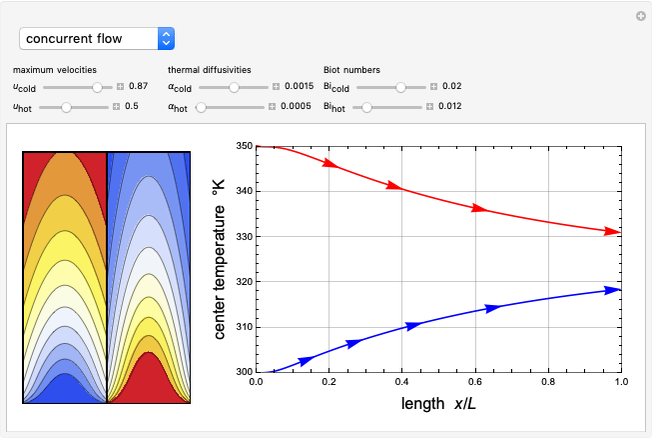

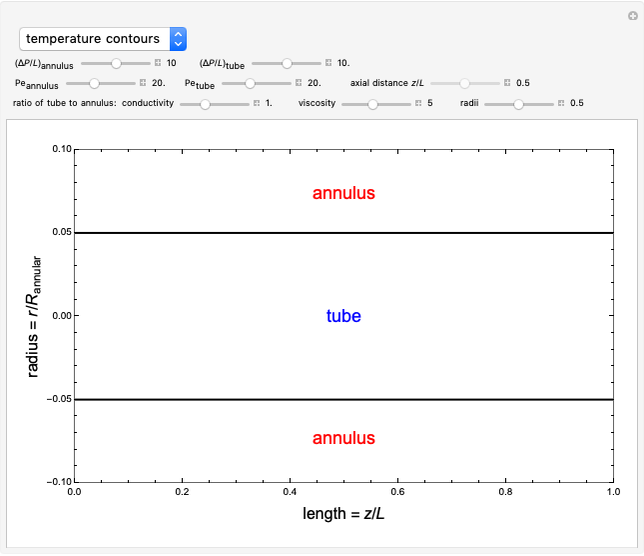

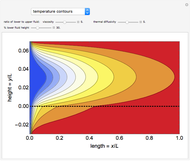

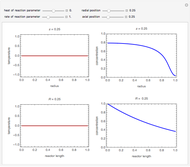

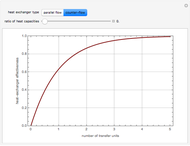

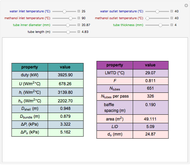

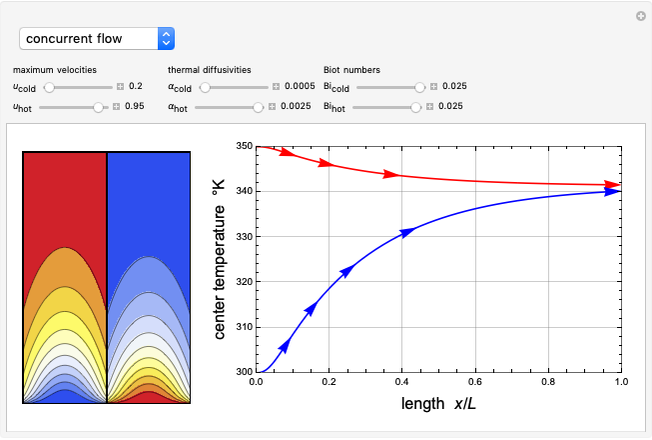

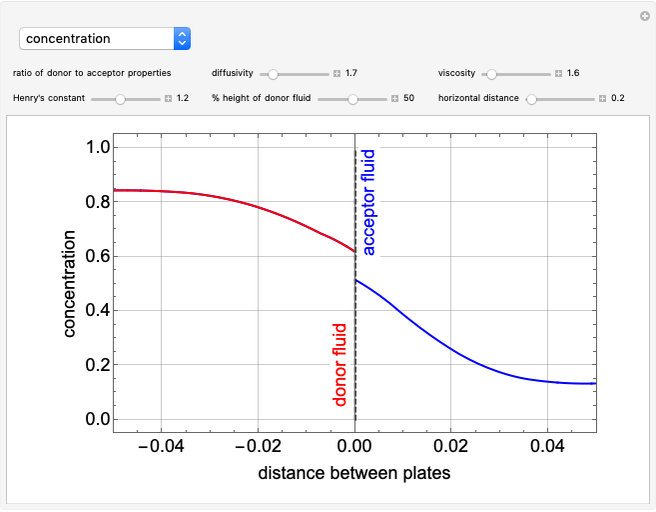

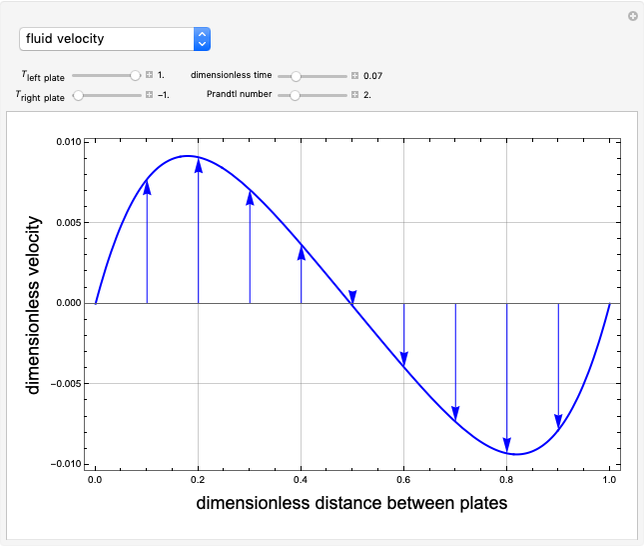

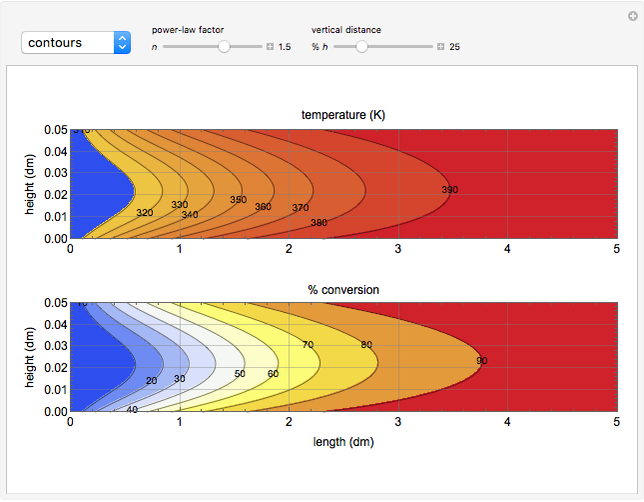

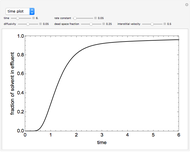

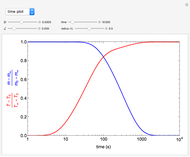

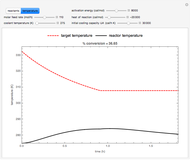

Parallel plate heat exchangers are widely used in chemical, pharmaceutical and food processing. They consist of a series of metal plates placed parallel to each other to allow the formation of a series of channels through which hot and cold fluids flow to transfer heat. This Demonstration illustrates the temperature distribution of two fluids in concurrent and countercurrent laminar flow in adjacent channels using a system of coupled boundary value and initial value partial differential equations.

Contributed by: Clay Gruesbeck (January 2021)

Open content licensed under CC BY-NC-SA

Snapshots

Details

The properties of the two liquids are assumed to be constant, and their velocity profiles are assumed to be independent of axial location. In the inlet region, the liquids in adjacent channels are in laminar flow and have different temperatures.

The energy equations for the two fluids are:

and

.

.

Here the subscripts  and

and  stand for hot and cold,

stand for hot and cold,  and

and  are the fluid thermal diffusivities, and

are the fluid thermal diffusivities, and  is one-half the distance between plates. The dimensionless horizontal and vertical distances are:

is one-half the distance between plates. The dimensionless horizontal and vertical distances are:

and

,

,

where  is the length of the plate,

is the length of the plate,  and

and  are the horizontal and vertical distances respectively, and the velocities of the hot and cold fluids are

are the horizontal and vertical distances respectively, and the velocities of the hot and cold fluids are

and

,

,

where  and

and  are the maximum velocity of the two fluids. The boundary conditions for the equation for the cold fluid are

are the maximum velocity of the two fluids. The boundary conditions for the equation for the cold fluid are

,

,

,

,

and

,

,

while for the hot fluid in concurrent flow:

,

,

,

,

and

.

.

In countercurrent flow, two boundary conditions must be changed:

and

.

.

is the Biot number, the ratio of the heat transfer resistance inside of a body and at the surface.

is the Biot number, the ratio of the heat transfer resistance inside of a body and at the surface.

These equations are solved with the built-in Wolfram Language function NDSolve. You can vary the values of the fluid velocities, diffusivities and Biot numbers to observe their effect on the temperatures of the fluids.

Permanent Citation