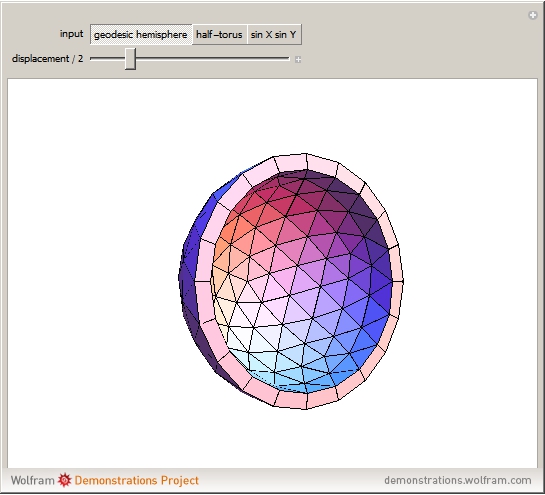

Thickening a Polygon Mesh for Rapid Prototyping (3D Printing)

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

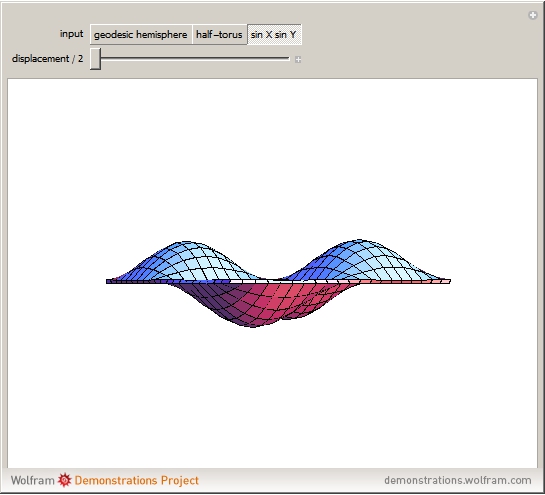

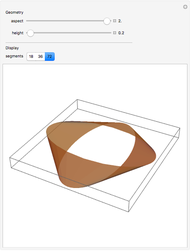

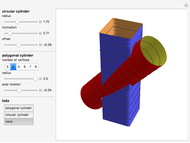

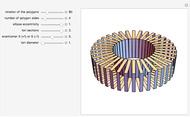

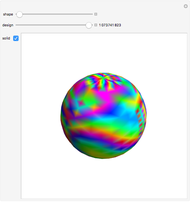

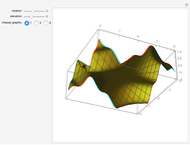

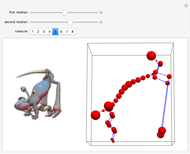

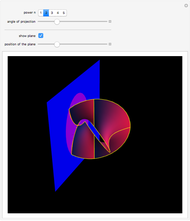

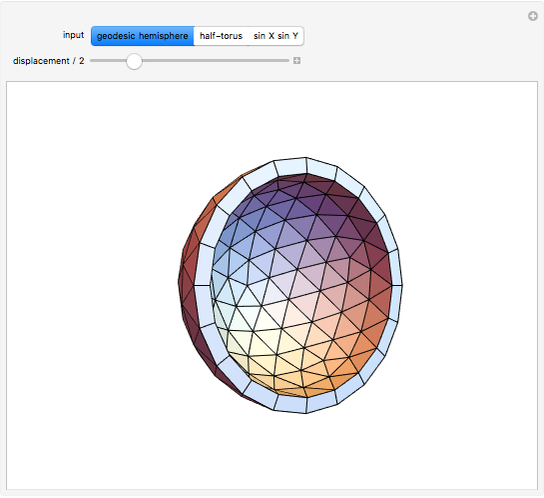

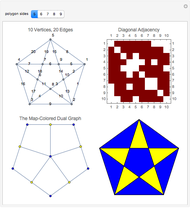

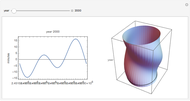

Most shapes can now be rendered physically via 3D CAD/CAM, but the output of most 3D parametric surface plots is not buildable by 3D printers in the original raw form. This Demonstration shows the operations for generating surfaces parallel to the parametric surface, then identifying the polygon edges at the open boundary of the surface and stitching the front and reverse surface copies together with a row of polygons to form a closed polyhedral surface. The result may be exported for 3D printing.

Contributed by: Stewart Dickson (December 2011)

Open content licensed under CC BY-NC-SA

Snapshots

Details

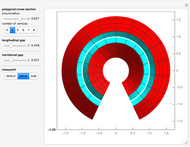

Polygon surfaces exported for rapid prototyping undergo a verification step to ensure that they are buildable. The object presented for 3D printing must be a closed, strictly manifold triangle mesh. This means that each edge connects exactly two polygons. Rapid prototyping machines construct replicas of 3D CAD models by laminating successive horizontal slices of the object from bottom to top. The object must produce a closed outline at every horizontal slice.

References

[1] I. Peterson, "Plastic Math," Science News, 140(5), 1991, pp. 72–73.

[2] M. Burns, Automated Fabrication: Improving Productivity in Manufacturing, Englewood Cliffs, NJ: Prentice Hall, 1993.

[3] A. Glassner, "Maintaining Winged-Edge Models," Graphics Gems II (J. Arvo, ed.), San Diego: Academic Press, 1991 pp. 191–201.

Permanent Citation

"Thickening a Polygon Mesh for Rapid Prototyping (3D Printing)"

http://demonstrations.wolfram.com/ThickeningAPolygonMeshForRapidPrototyping3DPrinting/

Wolfram Demonstrations Project

Published: December 19 2011