Operation of Heat Exchangers

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

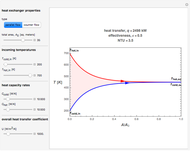

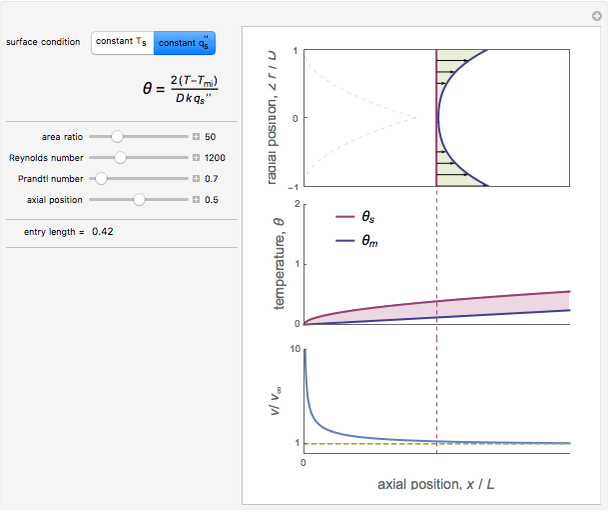

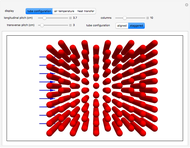

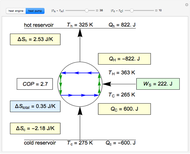

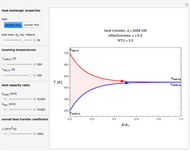

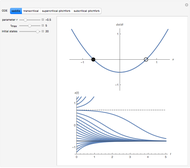

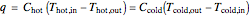

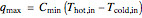

This Demonstration illustrates the effects of various input parameters on parallel-flow and counter-flow heat exchangers. It shows the temperature distribution and calculates the total heat transfer  , the effectiveness

, the effectiveness  , where

, where  , and the number of transfer units

, and the number of transfer units  , for both cases. By varying the input parameters, this tool lets you compare and understand the effects in these types of heat exchangers.

, for both cases. By varying the input parameters, this tool lets you compare and understand the effects in these types of heat exchangers.

Contributed by: Maximilian Jüngst and Brian Vick (November 2011)

Open content licensed under CC BY-NC-SA

Snapshots

Details

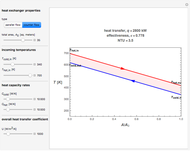

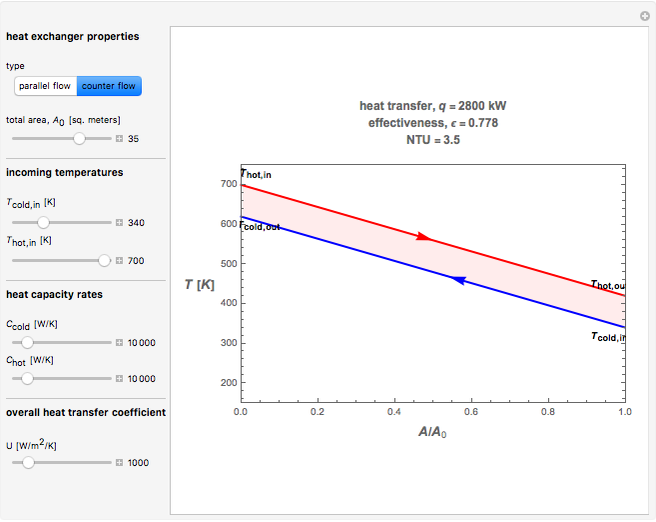

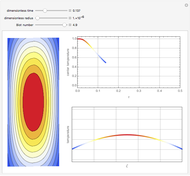

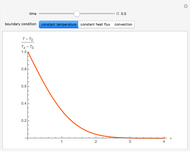

Snapshot 2: This has the same input as in snapshot 1, but for a counter-flow heat exchanger. The effectiveness and heat transfer are larger than the corresponding parallel-flow case, while the  is the same. It is also important to recognize that same heat capacity rates for the counter-flow effect a constant

is the same. It is also important to recognize that same heat capacity rates for the counter-flow effect a constant  through the whole heat exchanger.

through the whole heat exchanger.

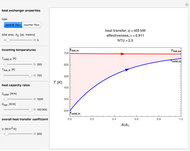

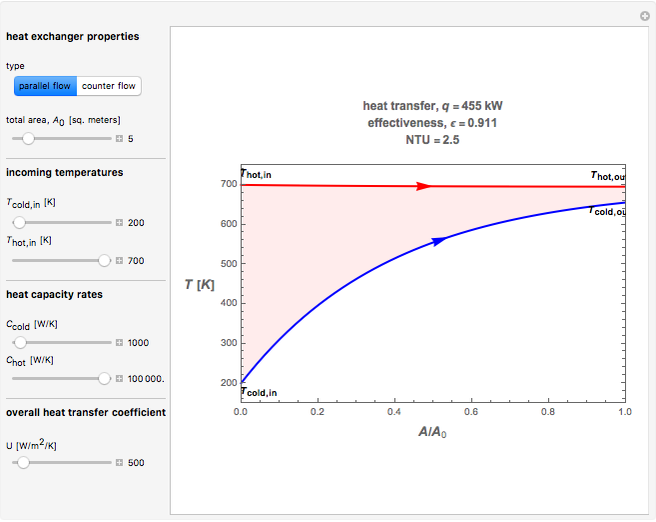

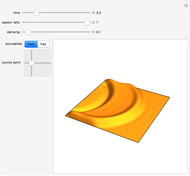

Snapshot 3: This snapshot shows the temperature distribution in a parallel-flow heat exchanger in which  . In this case the temperature of the hot flow is nearly constant through the heat exchanger.

. In this case the temperature of the hot flow is nearly constant through the heat exchanger.

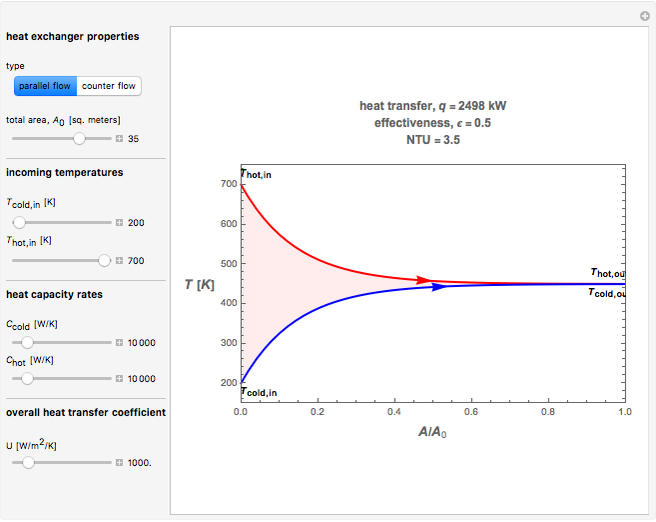

Snapshot 4: This has the same input as in snapshot 3, this time for the counter-flow heat exchanger. For  , the flow direction does not matter. The effectiveness, heat transfer, and

, the flow direction does not matter. The effectiveness, heat transfer, and  are the same in both parallel and counter flow arrangements.

are the same in both parallel and counter flow arrangements.

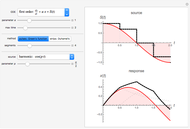

Snapshot 5: Limiting case: The overall heat transfer coefficient  . The fluids pass each other without any heat transfer.

. The fluids pass each other without any heat transfer.

As the chosen snapshots point out, this tool is useful for comparing different cases for parallel- and counter-flow heat exchangers, including limiting cases. It helps to understand the effects of various input parameters on temperature distributions, effectiveness, heat transfer, and  .

.

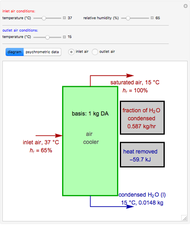

The temperature distribution is plotted versus the area ratio. The assumption for this model of heat exchangers is a one-dimensional flow for the hot and cold streams. This model can then be used if the fluids exchange heat through a plate or if they exchange heat by flowing through concentric tubes.

Permanent Citation