Production of Cis2-Butene and Cis2-Hexene by Cis2-Pentene Disproportionation

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

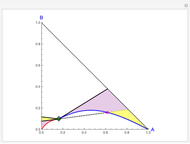

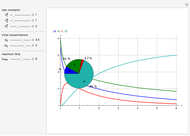

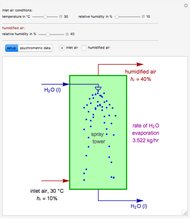

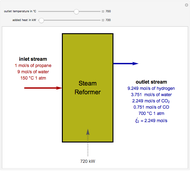

Consider an ideal ternary mixture composed of components cis2-butene ( ), cis2-hexene (

), cis2-hexene ( ), and cis2-pentene (

), and cis2-pentene ( ). This mixture is subject to an equilibrium-limited chemical reaction

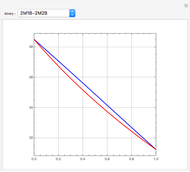

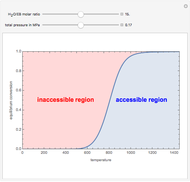

). This mixture is subject to an equilibrium-limited chemical reaction  (metathesis or disproportionation of olefins: 2

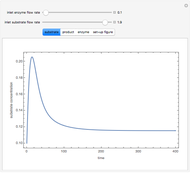

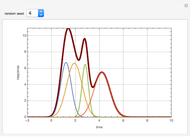

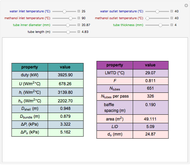

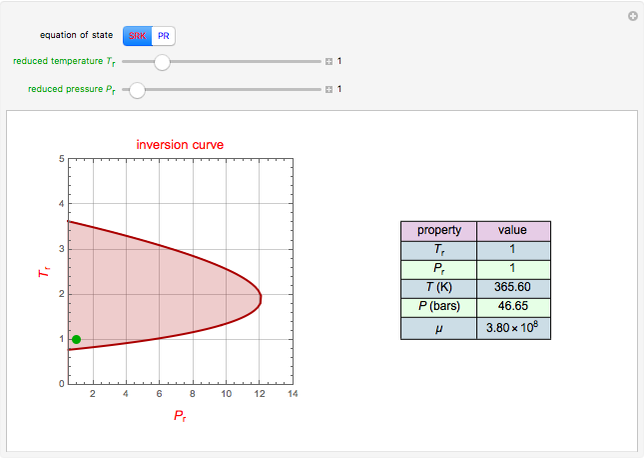

(metathesis or disproportionation of olefins: 2  cis2-pentene ⇌ cis2-butene + cis2-hexene) with reaction rate

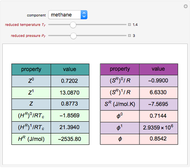

cis2-pentene ⇌ cis2-butene + cis2-hexene) with reaction rate  , where the equilibrium constant

, where the equilibrium constant  and

and  , with

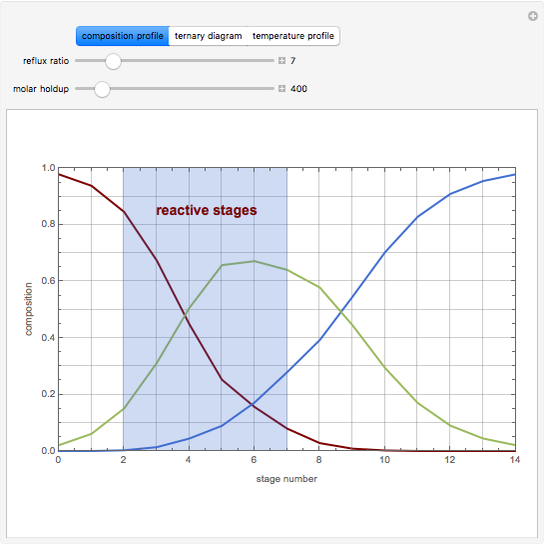

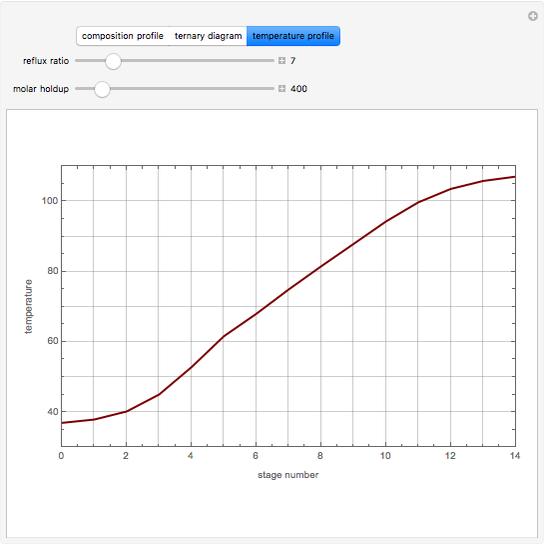

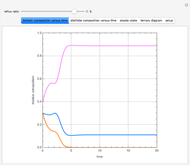

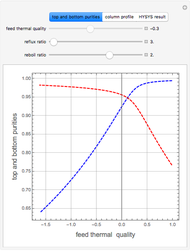

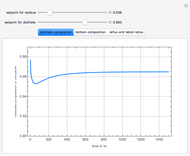

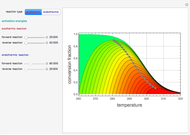

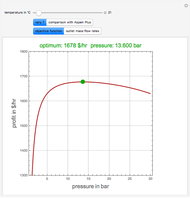

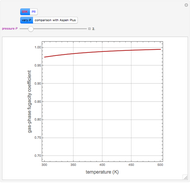

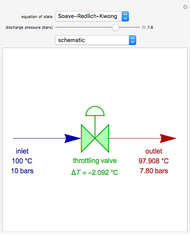

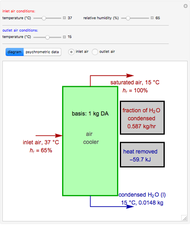

, with  cal/(mol K). This mixture is fed to a reactive distillation column operating at a pressure of 3 atmospheres with 13 plates; the feed stage location is stage 5, the reactive stages go from stages 2 to 7, and the feed composition contains 100% mole

cal/(mol K). This mixture is fed to a reactive distillation column operating at a pressure of 3 atmospheres with 13 plates; the feed stage location is stage 5, the reactive stages go from stages 2 to 7, and the feed composition contains 100% mole  or pure cis2-pentene. The feed flow rate is chosen to be 100 kmol/hr. For simplicity, we assume constant molal overflow (CMO) and neglect heat effects.

or pure cis2-pentene. The feed flow rate is chosen to be 100 kmol/hr. For simplicity, we assume constant molal overflow (CMO) and neglect heat effects.

Contributed by: Housam Binous, Manel Selmi, Ines Wada, and Ahmed Bellagi (March 2011)

Open content licensed under CC BY-NC-SA

Snapshots

Details

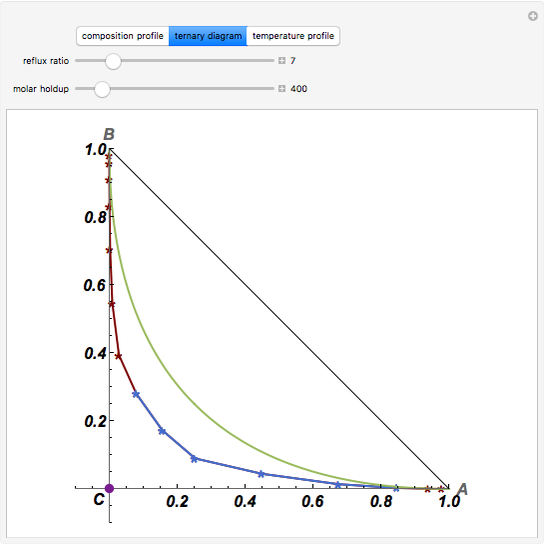

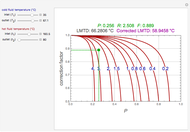

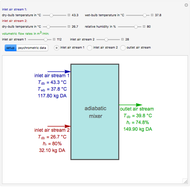

One snapshot shows a case where one obtains the two products  and

and  as distillate and bottom, respectively.

as distillate and bottom, respectively.

For more information, see

M. F. Doherty and M. F. Malone, Conceptual Design of Distillation Systems, New York: McGraw–Hill, 2001.

R. M. Dragomir and M. Jobson, "Conceptual Design of Single-Feed Kinetically Controlled Reactive Distillation Columns," Chemical Engineering Science, 60(18), 2005 pp. 5049–5068.

Permanent Citation