Continuous Stirred Tank Reactor with Activated Sludge Recycle

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

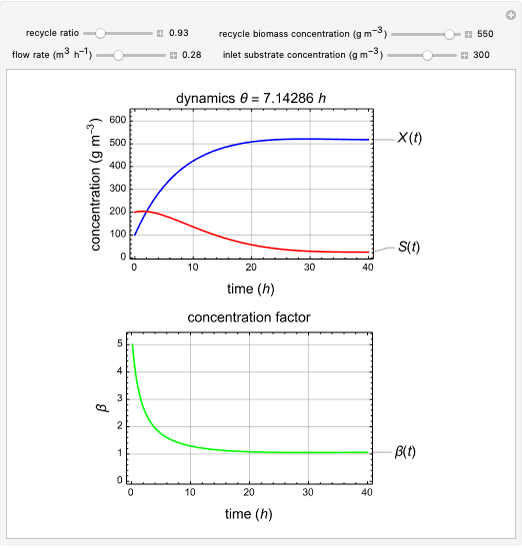

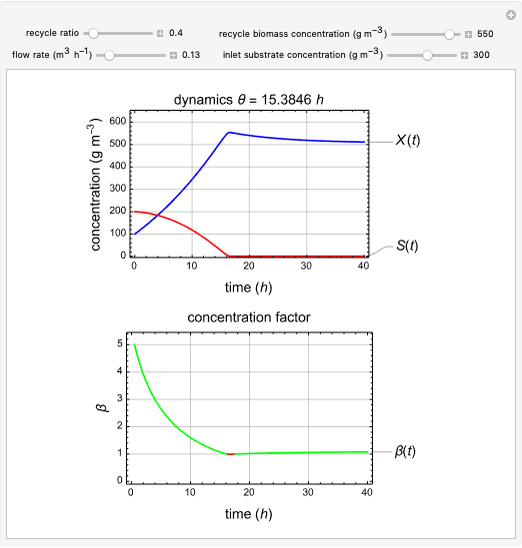

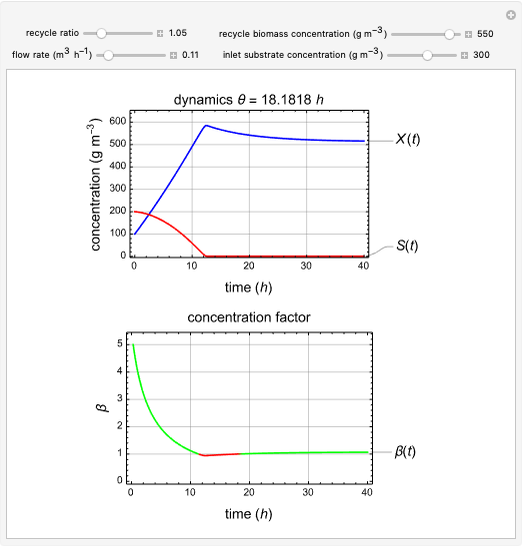

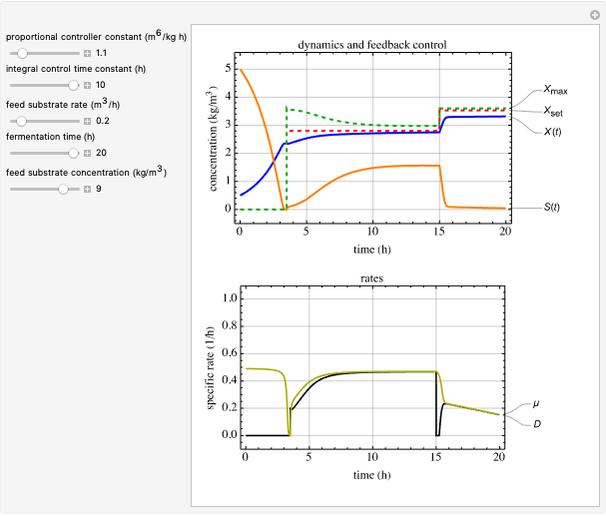

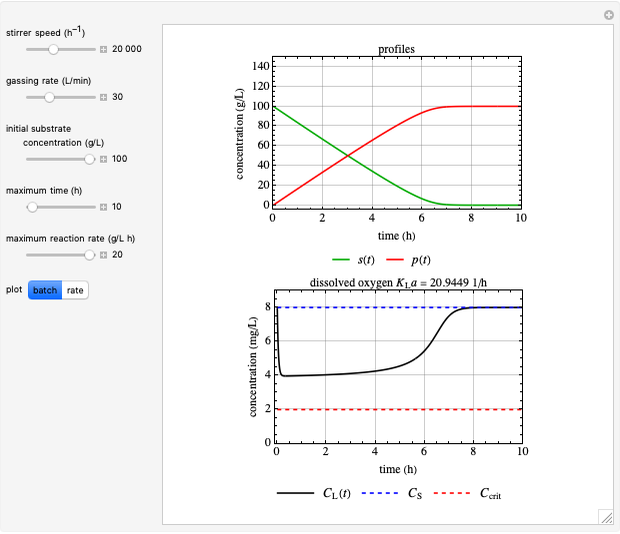

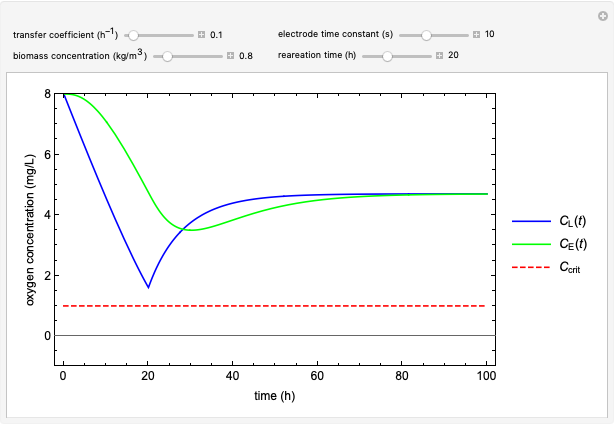

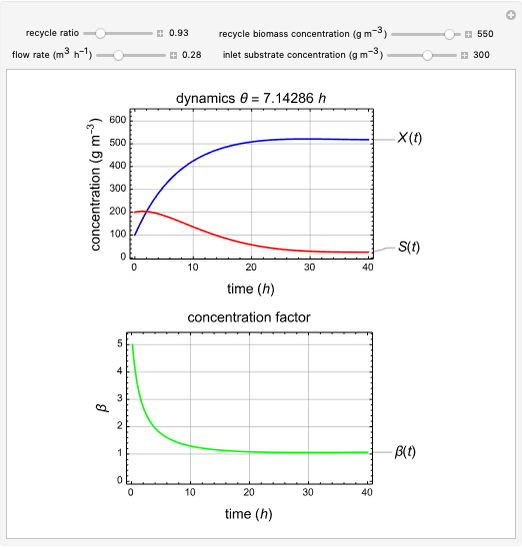

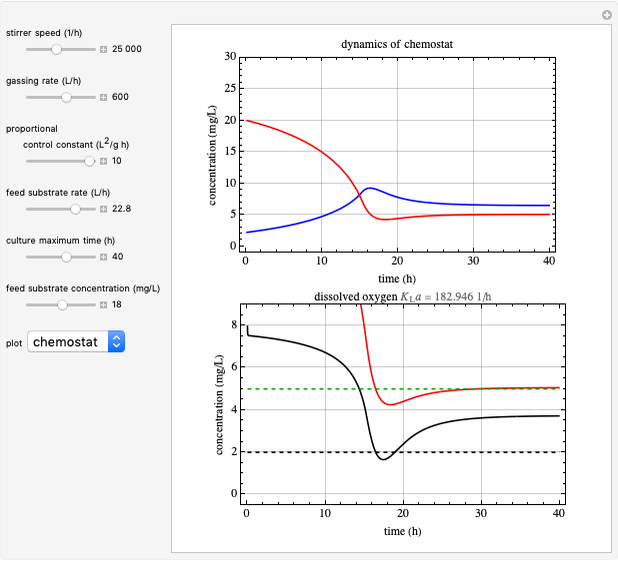

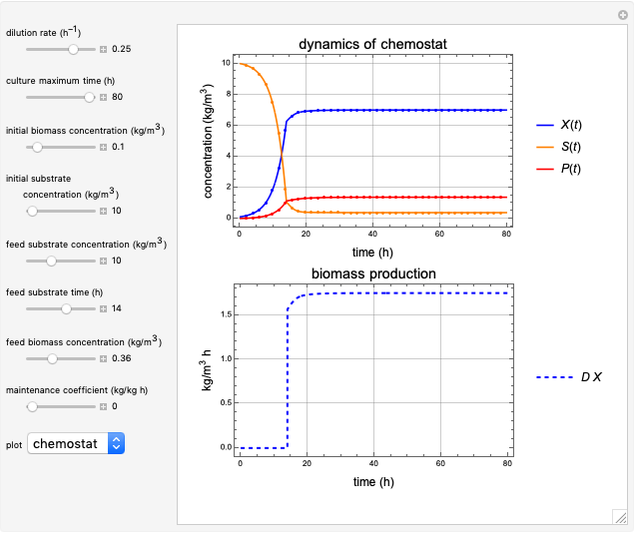

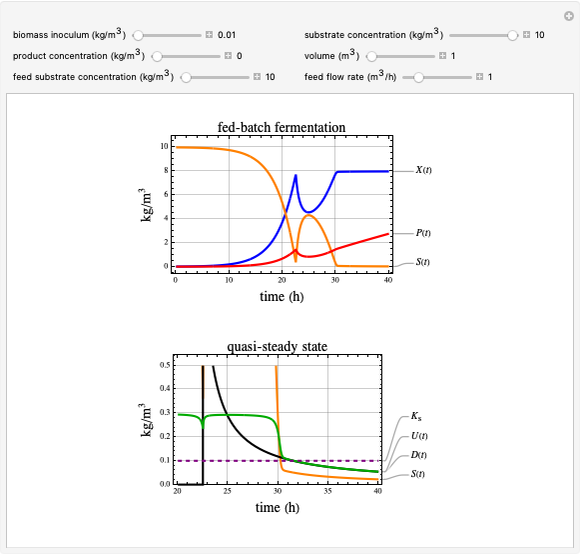

This Demonstration considers a model for the dynamics of a continuous stirred aeration tank processing activated sludge.

[more]

Contributed by: R. Ricardo Sánchez (August 2022)

Open content licensed under CC BY-NC-SA

Snapshots

Details

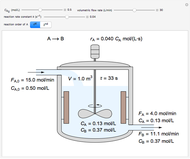

The volumetric flow rate entering and leaving the reactor  is the sum of the influent

is the sum of the influent  and recycle flow

and recycle flow  rates:

rates:

.

.

The recycle ratio is defined by:

.

.

Then:

.

.

The reactor residence time is defined as the volume of the reactor divided by the volumetric influent flow rate:

.

.

The concentration factor  is defined as the ratio of the recycle biomass to effluent biomass concentrations:

is defined as the ratio of the recycle biomass to effluent biomass concentrations:

.

.

Notation:

: biomass concentration in reactor (

: biomass concentration in reactor ( ),

),

: substrate concentration (

: substrate concentration ( ),

),

: sludge concentration factor (dimensionless),

: sludge concentration factor (dimensionless),

: recycle ratio (dimensionless).

: recycle ratio (dimensionless).

The model is described in detail in [1, Exercise 3.3.2].

Suggestions for further exploration:

1. Vary the recycle ratio to see how the performance of the process is influenced.

2. Vary the values of the flow rate to see how the process is influenced.

Reference

[1] J. B. Snape, I. J. Dunn, J. Ingham and J. E. Prenosil, Dynamics of Environmental Bioprocesses: Modelling and Simulation, New York: VCH, 1995.

Permanent Citation