Estimating Cohesion and Tensile Strength of Compacted Powders

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

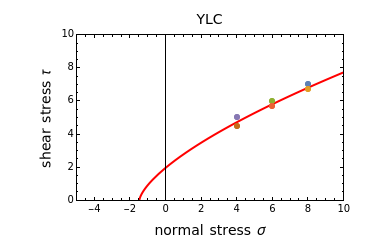

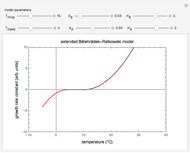

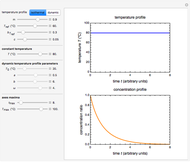

The flowability of a cohesive powder is determined by shearing specimens compacted and tested under various compressive loads. The resulting family of yield shear stress versus the compressive normal stress relationships, known as the yield loci curves (YLCs), is used to calculate the principal stresses from which the flow function of the powder is constructed.

[more]

Contributed by: Mark D. Normand and Micha Peleg (September 2017)

Open content licensed under CC BY-NC-SA

Snapshots

Details

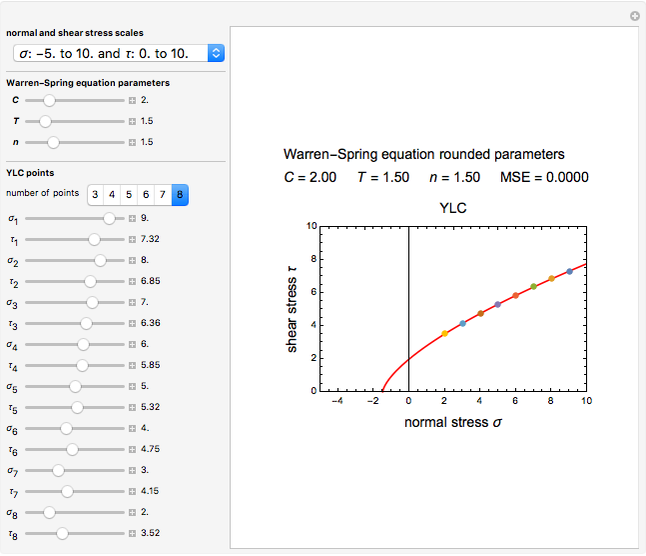

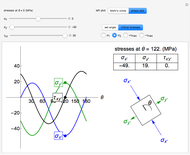

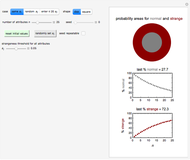

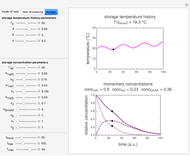

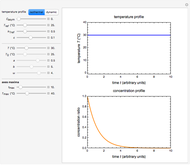

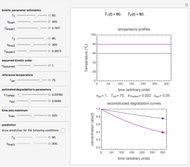

Snapshot 1: ideal match between shear data and a YLC both generated with the default parameters and the Warren–Spring equation as a model

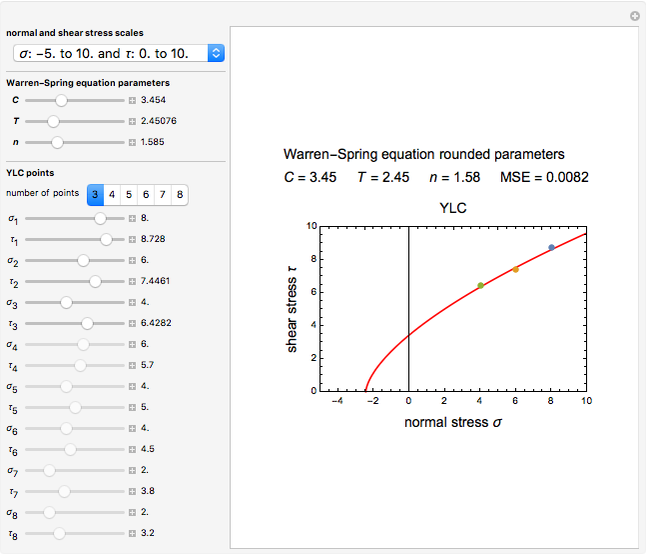

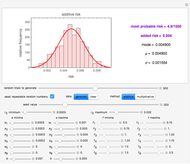

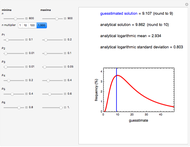

Snapshot 2: YLC of a cohesive powder produced by matching three data points

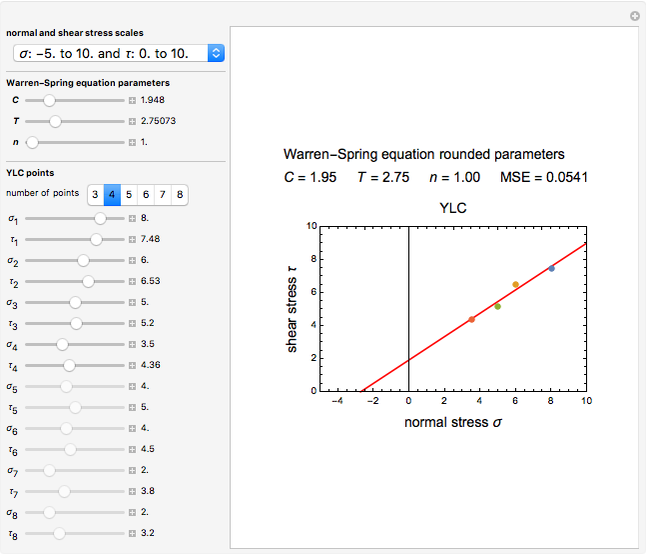

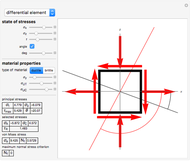

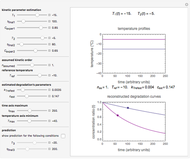

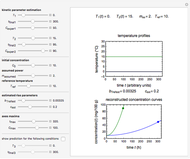

Snapshot 3: linear YLC ( ) of a cohesive powder

) of a cohesive powder

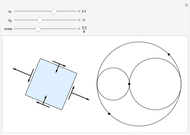

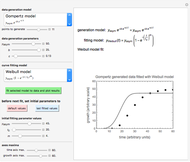

Snapshot 4: YLC of an almost perfectly free-flowing powder. Notice that  and

and  are not allowed in the model.

are not allowed in the model.

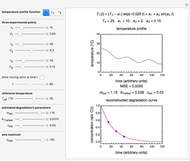

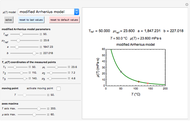

Quantification of the flowability of a cohesive powder is based on shear analysis of compacted specimens [1, 2] which gives a family of yield loci curves (YLCs). These are used to calculate pairs of principal stresses, the major consolidation stress and unconfined yield strength, for each consolidation level, derived from two constructed Mohr semicircles, tangent to the YLC.

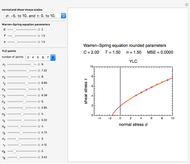

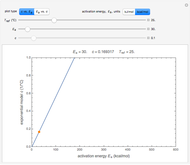

These pairs in turn are used to construct  , the flow function of the powder, which together with the effective angle of internal friction, also calculated from the YLCs, serves as a tool in bin design [1, 2]. When the YLC can be described algebraically, the two Mohr semicircles and related parameters can be calculated by numerically solving pairs of nonlinear equations [3], using a procedure that is available in [4]. The YLCs of many compacted powders can be described by the Warren–Spring equation

, the flow function of the powder, which together with the effective angle of internal friction, also calculated from the YLCs, serves as a tool in bin design [1, 2]. When the YLC can be described algebraically, the two Mohr semicircles and related parameters can be calculated by numerically solving pairs of nonlinear equations [3], using a procedure that is available in [4]. The YLCs of many compacted powders can be described by the Warren–Spring equation

,

,

where  and

and  are the shear and normal compressive stresses, respectively,

are the shear and normal compressive stresses, respectively,  is the cohesion,

is the cohesion,  is the tensile strength, and

is the tensile strength, and  is the curvature index [5].

is the curvature index [5].

When  has been determined experimentally with a special instrument, and there are a sufficient number of points along the YLC, the Warren–Spring equation parameters

has been determined experimentally with a special instrument, and there are a sufficient number of points along the YLC, the Warren–Spring equation parameters  and

and  can be determined by nonlinear regression. This, however, is not always a practical option, and hence the need to estimate all three from a few experimental points.

can be determined by nonlinear regression. This, however, is not always a practical option, and hence the need to estimate all three from a few experimental points.

The purpose of this Demonstration is to estimate  ,

,  and

and  by visually matching three or more experimental shear stress-normal stress data points with a corresponding YLC generated using the Warren–Spring equation as a model. The visual match is assisted by a displayed mean squared error (MSE) for fine tuning.

by visually matching three or more experimental shear stress-normal stress data points with a corresponding YLC generated using the Warren–Spring equation as a model. The visual match is assisted by a displayed mean squared error (MSE) for fine tuning.

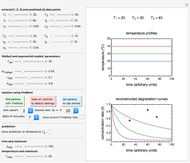

To start, select the normal and shear stress ranges from the popup menu. Then select the number of YLC points to be entered using its setter bar. If the scale has been changed, the graphic display will be of a YLC generated using the Warren–Spring equation with the default parameter values, along with the chosen number of points at their initial default locations.

Next, enter the coordinates for the data points  and

and  . Once they are all entered, move the

. Once they are all entered, move the  ,

,  and

and  sliders until a match has been reached. For increased accuracy, you can adjust the numerical value of the parameter after clicking the digit or digits to be altered. The final positions of the sliders are the sought

sliders until a match has been reached. For increased accuracy, you can adjust the numerical value of the parameter after clicking the digit or digits to be altered. The final positions of the sliders are the sought  ,

,  and

and  estimates.

estimates.

Note that not all allowed entered values of  and

and  can achieve a match using realistic

can achieve a match using realistic  ,

,  and

and  parameter values.

parameter values.

References

[1] J. C. Williams, "The Storage and Flow of Powders," in Principles of Powder Technology (M. J. Rhodes, ed.), New York: Wiley, 1990.

[2] J. Schwedes, "Review on Testers for Measuring Flow Properties of Bulk Solids," Granular Matter, 5(1), 2003 pp. 1–43. doi:10.1007/s10035-002-0124-4.

[3] M. Peleg, M. D. Normand and M. G. Corradini, "Interactive Software for Calculating the Principal Stresses of Compacted Cohesive Powders with the Warren–Spring Equation," Powder Technology, 197(3), 2010 pp. 268–273. doi:10.1016/j.powtec.2009.10.003.

[4] M. D. Normand and M. Peleg. "Principal Stresses in Compacted Cohesive Powders" from the Wolfram Demonstrations Project—A Wolfram Web Resource. demonstrations.wolfram.com/PrincipalStressesInCompactedCohesivePowders.

[5] M. D. Ashton, D. C.-H. Cheng, R. Farely and F. H. H. Valentin, "Some Investigations into the Strength and Flow Properties of Powders," Rheologica Acta, 4(3), 1965 pp. 206–218. doi:10.1007/BF01969257.

Permanent Citation